The all in one brewpub brewing equipment is made of food grade 304 stainless steel. It provides turnkey projects from selecting high-quality large malt to malt crushing system, mash system, fermentation system, CIP cleaning system, control system, filling system, etc.All in one beer equipment belongs to micro beer equipment, which is mainly sold in bars, restaurants, hotels, barbecue shops and other places. The equipment has small volume and compact structure. The shape of beer equipment can also be designed according to the decoration in the store, so as to integrate the appearance of the equipment with the style in the store, improve the style of the store and attract consumers.

The emergence of refined beer can better reflect its personalized and diversified logo. A single taste of beer can no longer meet the needs of today's young people. It can better show that it is a kind of culture and a kind of spiritual sustenance. It is not only the expression of the quality of life, but also the embodiment of personal taste. Fine brewed beer originated in the United States and transformed large-scale production into a beer with small population, localization, pursuit of quality, pursuit of individuality and multiple flavors without adding any preservatives.

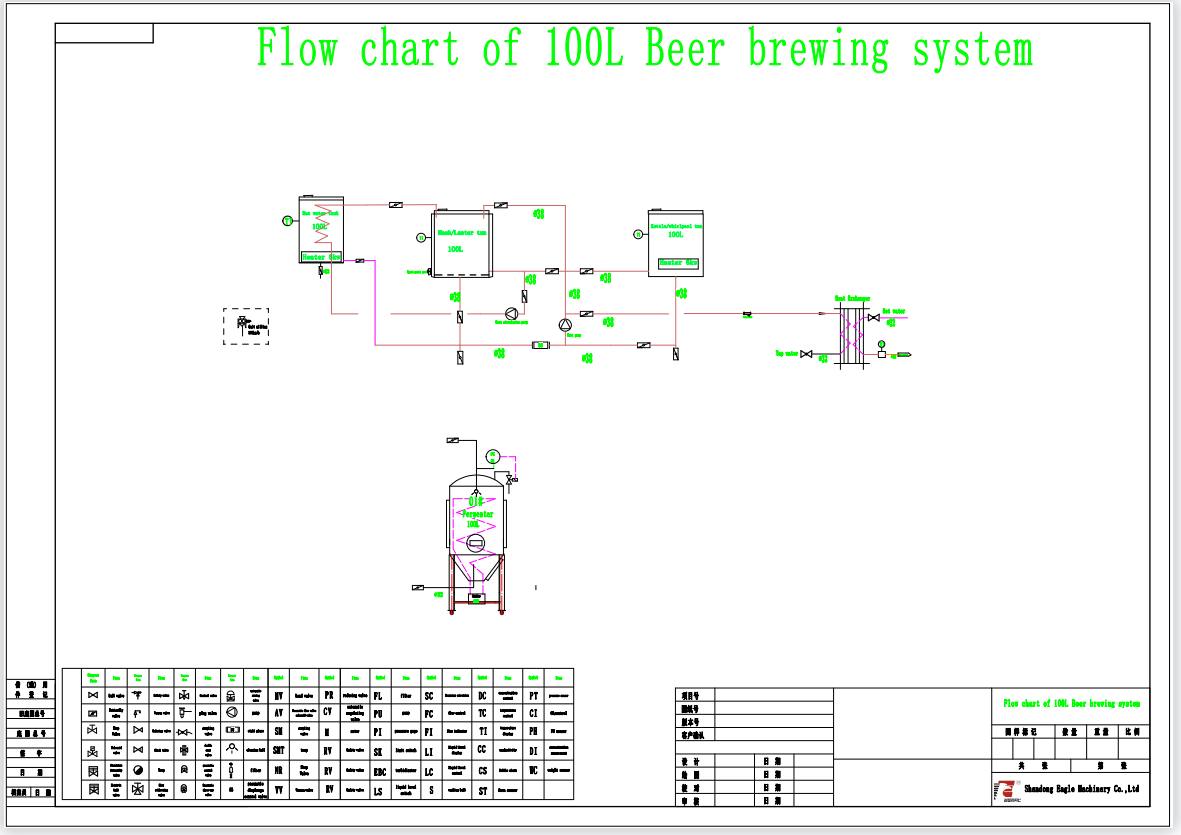

Name | Specification | Qty | Material | Technical Parameters | |||

Mash system |

Main part |

01 |

Mash/Lauter tun |

100L |

1 | Stainless steel | Dimensions: φ500×800; total volume is 120L; effective volume is 100L. Comes with temperature control and automatic heating. Spent grain spot |

02 |

Kettle tun |

100L |

1 |

Stainless steel | Dimensions: φ500×800; total volume is 120L; effective volume is 100L. | ||

03 |

Hot liquid tank

|

100L |

1 |

Stainless steel | Dimensions: φ500×800; total volume is 120L; effective volume is 100L. temperature control and automatic heating, with a coil tube to control the temperature | ||

01 | Malt milling | 100Kg/h |

1 | Carbon steel | Grinding disc type crushing, motor power 1KW. | ||

02 |

Wort pump | Flow 1m3/h, head 8m |

2 | Stainless steel | 400V, 50Hz, 0.55kW, frequency conversion speed regulation; inlet φ38, outlet φ32 clamp connection | ||

03 | Plate heat exchanger

| BR0.1/5 1㎡ | 1 | Carbon steel | Two-stage 6-lead,; Ice water inlet and outlet G3/4, tap water inlet G1, tap water outlet φ25 clamp, wort inlet and outlet φ25 clamp | ||

Accessories | 01 | Mash pipeline | ISO:Φ38/Φ32 | 1 | Stainless steel | Sanitary stainless steel valves and pipelines, welded on one side and formed on both sides | |

02 | Wort Thermometer | WNG/WNY(0~100℃) | 1 | Glass/Stainless steel | Stainless steel metal casing thermometer | ||

04 | Measuring cylinder | φ32 | 1 | Stainless steel | L=350 | ||

05 | Saccharimeter | 10°、20° | 2 | Glass | / | ||

06 | 出糟耙 Grain Harrow

| L=1300 | 1 | 不锈钢 Stainless steel | / | ||

Fermentation system |

Main part |

01 |

Fermenter |

100L |

1 |

Stainless steel | Single tank with single control, overall size: φ650×1300; total volume 130L, effective volume 100L, insulation thickness 70mm; liner thickness: 2mm; liner drawing and polishing, outer 1.5mm oil grinding wire drawing board, welding seam polishing belt ; Equipped with sampling valve, positive and negative pressure safety valve, valve and accessories. |

Accessories | 01 | Food grade hose | Ф32 (Inside diameter) | 1 | Plastic | Matching hose connector, 5 meters | |

01 | Pipeline | Ф32 | PPR | / | |||

02 | Valve | Ф32 | stainless steel | / | |||

03 | Insulated pipe | Ф32 (Inside diameter) | Polyethylene | With PAP board and tape | |||

01 | Pipes, valves | Ф38/Ф32 | 1 | stainless steel | Sanitary | ||

Control system | 01 | Control cabinet | 500×200×300 | 1 | Spay Plastic | Mash | |

01 | Inflatable head | Ф32/φ10 | 2 | stainless steel | Clamp connect | ||

02 | Inflation hose | Ф12 | 5 | Tube | |||

The above parameters take 100L as an example, and the configuration table is for reference only. The specific requirements shall be determined according to the customer's requirements. The customer's site, budget, specific equipment and other requirements to determine the configuration.It can customed according to client's requirementWelcome to consult and communicate the detailed configuration.

The drawings are for reference only. We will design them separately according to your requirements

One vessel one pot

One vessel one pot refers to the saccharification filtration boiling rotary sedimentation process of the saccharification system. It is composed of one pot, It can also be composed of saccharification / filtration pot and boiling / rotary sedimentation pot. One pot is made into two layers, with saccharification / filtration pot on the top and boiling / rotary sedimentation pot on the bottom,which has the characteristics of small floor area and simple operation.

This saccharification system is two body and two vessel saccharification. One pot is saccharification / filtration pot, and the other pot is rotary sedimentation / boiling pot. This is generally American saccharification system, which can improve work efficiency and be more convenient to use.

This saccharification system is a two body three vessel saccharification system. One pot is a saccharification / boiling pot, the other pot is a filter pot above and a rotary sink pot below. This is generally a German saccharification system, which is more widely used. It can not only save cost, easy to use, simple operation and continuous work.

The saccharification system can also be made into three bodies, three devices and four bodies, which is suitable for 2-4 batches of production every day, suitable for continuous work and simpler operation.

Selection of mash system for all in one beer equipment

The mash system should be determined according to the customer's site, daily production output, daily production batch, customer's use habits, budget, etc. when you choose to be a bar, you must tell us your needs, and we will design the best scheme for you, so that you can use it more comprehensively and brew more unique beer.

Number of fermentation tanks

The number of fermentation tanks is determined by the batch produced every day and the type of beer produced. For example, for the 500L beer system, two batches are made every day. For each batch, we suggest to use 6 fermentation tanks, and 12 fermentation tanks are required for two batches.

Cooling system of fermentation tank

The fermentation system is one of the key steps to form beer. During the fermentation process, beer must be kept at about 8 degrees, which requires high cooling requirements. We generally use the liquid of ethylene glycol after alcohol to cool in the evaporator box of ammonia refrigerator, and the temperature is generally controlled at about - 5C. It is mainly used for wort cooling and fermentation tank cooling.

Each customer's scheme is different. The above scheme is only for reference. If you first make refined beer and want to open a bar, and don't know how to choose equipment, please tell us your needs. We provide turnkey service, from malt selection, beer equipment design, filling, labeling, etc,

If you want to ask anything just fill in the form below and send us.