668.jpg)

A complete set of 500L beer equipment consists of malt crushing system, saccharification system, fermentation system, steam system, refrigeration system, CIP cleaning system, pipeline system, etc. 500L brewing beer equipment is generally used in commercial, restaurants, bars, barbecue shops and other places.

Malt milling system and mash system of 500L brewery system for craft

Name | Formation | Spec | Detailed information |

Pre-processing system | Malt Crusher | 100Kg/h | Roller type, stainless steel. |

Mash &kettle&tun |

working capacity:500L | 1. Inner material SUS304, 3mm, thick brass as outer material;Dimensions: D = 1260mm, H = 2550mm. 2. Electric heating, power 36KW. meets the temperature rise of 1-1.5 degrees / min 3. Insulation rock wool, the thickness of the insulation laminate is 80mm. 4. More than 40% of the air capacity 5. The speed of the stirring motor is 30r/min. The stirrer in the tank is made of stainless steel 304. The lower part of the stirring shaft supports the bushing. The upper part of the pot has a seal to prevent steam from leaking from the shaft. 6. The upper steam discharge pipe has a diameter of 159, and a condensate collecting device is added to the steam discharge pipe, and the drain pipe is embedded in the heat preservation layer. 7. The bottom feed 8. Temperature sensor, -10--150 ° C, 4-20 mA signal, L = 200 mm, 50.5 chuckconnection,Brand: Fred 9. Inside the equipment 2B surface, pickling passivation treatment, welds after fine treatment, no deformation, etc.;external surface wire drawing treatment, equipment appearance, pipe layout, opening position, etc. meet the operation, on-site installation and visit requirements 10.Round glass manhole, dish-shaped head 11.With a cleaning tube, with standard ball washing, cleaning pipeline ISO32,integrated searchlight sight glass | |

Mash system |

Lauter&whirlp ool tun |

working capacity:500L | 1. The effective part of the filtering part is 500L, and the effective volume of the spin-drying part is 500L 2. The inner material SUS304, Outer material, brass; outer dimensions: D = 1260mm, H = 2750mm. 3. Filter part of rock wool insulation, thickness 80mm 4. The upper 2 inlet tubes, one for reflux and washing. The internal washing device is in the form of a double umbrella plate, and the second washing tube is used for the washing of the filter tank, and is equipped with a standard washing ball ISO32 5. The filter has the upper circular mirror manhole, the side square out of the mouth (spent grains chute); the filter discharge main pipe with the audition and the sanitary sampling valve, the mirror is installed horizontally; the filter can achieve natural filtration and suction filtration, The natural washing can synchronize the washing 6. Filter plate: milling. Material SUS304, the opening ratio is about 10%; the surface is bright and flat; the part can be opened, the cleaning is convenient, the use is not deformed; the distance between the filter plate and the bottom of the pot is between 2-5cm, the bottom of the tank is provided with a bottom cleaning device, uniform Not less than three. 7. Tillage device: The overall material is stainless steel 304; the installation and support are firm, the rotation is stable; the speed control is variable; the inclination angle of the tilling knife is ≤ 15°; the internal tillage frame is fixed to the cylinder of the tank, not the bottom; the stirring motor and Gearbox jacket stainless steel 304 shield. Motor and gearbox speed 30r/min, choose domestic famous brand. Turning farming lees forward, reversing row lees 8. The counter-clockwise tangential feeding, the feeding port is one-third of the liquid level; the liquid level pipe has a breathing hole, and The shape of the bottom and the discharge ensure the convenience of operation and increase the convenience of operation while reducing the liquid loss. There is a bypass between the sinking discharge pipe and the sewage pipe; Teflon liquid level pipe 9. Inside the equipment 2B surface, pickling passivation treatment, welds after fine treatment, no deformation 10.The spin-sink has a cleaning tube with standard ball washing ,searchlight sight glass ,ISO32 cleaning line. |

Hot water tank |

Working capacity 1000L | 1. The material of the inner tank is SUS304, 3mm, and the thickness of the outer packaging material is 2mm; the external dimensions: D = 1160mm, H = 2500mm. 2. Rock wool insulation 80mm. 3. Conical head, round manhole. 4. Electric heating tube heating, | |

Plateheatexchanger | 1. Suspended. Design pressure 1.0mpa, design temperature 150 degrees; flow rate 2T / H. 2. The plate and frame material are 304 stainless steel. 3. The heat exchange area and process combination are satisfied: the wort is reduced from 98 degrees to 8-10 degrees, and it is finished in 40 minutes. The water rises from 2 degrees to above 65 degrees; the cooling water temperature is -5 ℃. 4. Both the wort inlet and the cold water inlet use ball valves to control the flow, and the wort temperature uses a digital display thermometer. | ||

Wort oxygenator | Venturi principle material SUS304, oxygen even and detailed, with glass sight glass, oxygenation can be visualized. | ||

Yeast adding tank |

10L Yeast added pipes, valves, meters | 1. Can be active, rely on the gas to the yeast into the board after the wort line, materialquality SUS304 stainless steel. 2. The upper part can be opened and cleaned manually with an exhaust valve; the lower conical bottom; the outlet is equipped with movable transparent hoses, one for both, both yeast inand yeast out. Including valves, sight glass, pipe fittings, hand-held thermometer, temperature display, etc. | |

Wort pump |

3T/H | 1. The pump body and impeller material are SUS304 high-quality stainless steel, which meets the requirements of sanitary pumps and is a well-known domestic brand. 2. Frequency conversion control, flow rate 3 tons / hour, head 18 meters. |

Fermentation system of 500L brewery system for craft beer brewing

Fermentation system |

Fermenter |

working capacity:500L | 1. Inner material SUS304, thickness 3mm; Outer material SUS304, thickness 2mm; Dimensions: D = 1060mm, H = 2260mm / device manhole opening height 2530mm. 2. Miller plate jacket, material SUS304, thickness 1.5mm, cylinder cooling area is about 40% of the cylinder surface area, cone cooling area is about 50% of the cone surface area. 3. Polyurethane foam insulation, thickness 80mm 4. The pressure resistance of the tank is 2.5 bar. 5. Cone compression design at 60 ° 6. Air capacity 20%,the upper part of the cylinder is flush with the bottom of the ball. 7. Equipped with a washing ball, the installation position is slightly lower than the welding seam between the cylinder and the head, the cleaning tube Ø32 8. The internal roughness is ≤0.4um, and there is no deformation, no scratches, 2B side of the weld. 9. The upper part is equipped with manhole and positive and negative pressure safety valve, single head. 10.The tank is equipped with temperature sensor (-10--150 ℃, 4-20mA signal, L = 200mm, 50.5 chuck connection, brand Fred), sampling valve; sewage outlet at the bottom, wine valve and hop at the bottom of the cone Dry investment port DN100. 11.Bottom drain pipe Ø38 12.Inside the equipment 2B surface, pickling passivation treatment, welds after fine treatment, no deformation, etc.; external surface wire drawing treatment, equipment appearance, pipe layout, opening position, etc. to meet the operation, On-site installation and visit requirements. |

Mechanical valve | Material SUS304, mechanical pressure regulation, control the pressure in the fermentation tank, model WH-5101A (0.2-2.2bar), with flush membrane pressure gauge. | ||

CIP system | 1.One set mobile cleaning pump, with a control panel. stainless steel 304 |

Cooling system and others of 500L brewery system for craft beer brewing

2.Cleaning pump flow 2T / H, lift more than 20 meters, corrosion resistance. | |||

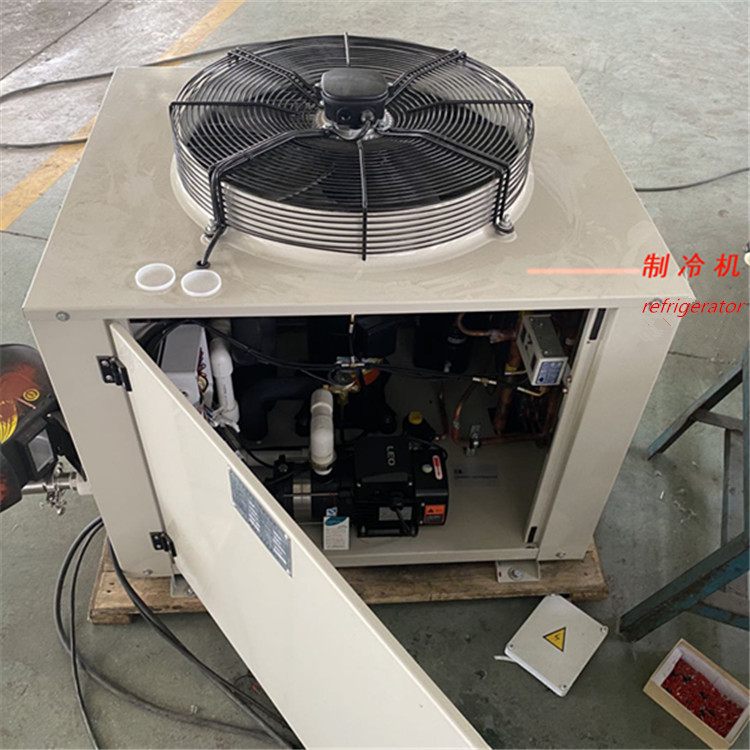

Cooling system | Chiller | 5P | 1. Unit type: air-cooled chiller, voltage level AC380v, 50hz, total input power 4.86KW. 2. Ability to meet requirements, outlet water temperature -5 ℃, nominal cooling capacity 5.94KW. 3. Dimensions (L * W * Hmm): 892 * 781 * 864 3. Outdoor installation, ambient temperature <35 ℃. 4. Compressor: fully enclosed scroll type, refrigerant R22. |

Alcohol water tank | 1500L | 1. The material of the inner tank is SUS304, 3mm, and the thickness of the outer packaging material is 2mm; the overall dimensions: D = 1460mm, H = 2500mm 2. Polyurethane foam insulation 80mm. 3. Automatic temperature control. 4. Matching valves and fittings, all pipelines are insulated | |

Alcohol water pump | Flow:3T/H,lift:18 meters | 1. Flow 3T/H, head 18M 2. Alcohol water circulation pump, the ability to meet the requirements. | |

Electric System |

Fermentation control |

Imported brand PLC and 10 inch screen touch screen joint control. | 1. To achieve two-stage heating, three-stage cooling special fermentationprocess; 2. Different fermentation curves can be preset for different beer so as to satisfydifferent fermentation processes. 3. The program can realize the setting of any cooling rate within 2-24 hours, so as to preventice in the tank and protect the yeast, and to meet the normal fermentationmechanism. 4. Can be achieved without fermentation fermentationprocess. 5. The fermentation temperature, time, and cycle of each stage can be arbitrarily set and modified. 6. Thesystemcapacitytomeetafermentationcycle. Thesystemcollects dataonceevery20 minutes and summarizes it. It can record all data in a fermentationcycle. 7. Traceability. 8. Accuracy error ± 0.3°C. |

Switchboard | Mashing and fermentation share a distribution cabinet | ||

Fermentation control solenoid valve |

3/4” |

Copper, fluoroplastic diaphragm, DC24V, 2 spares | |

Wire and Cable | Signal lines use the shielded wire | ||

threading pipe | Stainless steel decoration pipe, the size & number meet site installation requirements. | ||

Pipeline fittings | Mash line | Φ38 | material:AISI 304 pipeline ,including mash all valves and piping,not include insulation material |

The alcohol water line | Main pipeline Φ32 Branch pipeline Φ25 | material:AISI 304pipeline,not include insulation material | |

Rubber hose | Φ38 | Washing pipe 2 sets (2 m / 3 m) wort tube 1 set 10 m, Φ 38, withhold type fast loading standard connectors.Material: food grade. |

If you want to ask anything just fill in the form below and send us.