Beer equipment used in bars and restaurants is generally about 300l-2000l. Hotel beer equipment is used to produce fresh beer and filtered beer. This beer equipment is usually placed in places where consumers drink directly, such as restaurants, pubs, tourism and shopping centers. The appearance of the equipment is made of stainless steel, brass or red copper. The whole beer brewing equipment can also be placed behind the transparent glass partition for visitors to observe the whole brewing process, which can more attract consumers.

| Code | Name | No. | Component |

| 1 | Malt milling system | 1 | Malt milling machine |

| 2 | Mash system | 1 | Mash/kettle tun |

| 2 | Lauter/whirlpool tun | ||

| 3 | Hot liquor tank | ||

| 4 | Plate heat exchanger | ||

| 5 | Wort oxygenator | ||

| 6 | Yeast addition tank | ||

| 7 | Operation platform | ||

| 8 | Wort pump | ||

| 9 | Hot water pump | ||

| 3 | Fermentation system | 1 | Fermenter |

| 2 | Mixing tank | ||

| 3 | PRV | ||

| 4 | Vent valve | ||

| 4 | Cleaning system | 1 | Mobile cleaning cart |

| 5 | Cooling system | 1 | Chiller |

| 2 | Glycol water tank | ||

| 3 | Ice water pump | ||

| 6 | Electrical System | 1 | Fermentation auto control |

| 2 | Switchboard | ||

| 3 | Fermentation control solenoid valve | ||

| 4 | Temperature Sensor | ||

| 5 | Wire and Cable | ||

| 6 | Threading tube | ||

| 7 | Filling system | 1 | Bottle rinsing machine |

| 2 | Linear filling and capping machine | ||

| 3 | Linear sticker labeling machine | ||

| 4 | Conveyor system | ||

| 8 | Steam system | 1 | Electric steam boiler |

| 9 | Pipeline accessories | 1 | Mash, CIP, water pipeline |

| 2 | Glycol water pipeline | ||

| 3 | Steam pipeline | ||

| 4 | Air compression pipeline | ||

| 5 | Food grade hose | ||

| 6 | Other |

The crushing system is mainly composed of malt crusher, malt storage and feeding equipment. Small equipment can only be equipped with malt crusher. Small and medium-sized beer equipment is generally equipped with double roll crusher, and large equipment is equipped with four roll or five roll crusher of Shandong Jingying Machinery Manufacturing Co., Ltd. Crushing can be divided into dry powder and wet powder. Small and medium-sized beer equipment is generally dry powder. Malt is crushed for better dissolution. The malt is broken but not broken, and the wheat peel acts as a filter for wort filtration. Malt crushers used in hotels and restaurants generally use counter roll malt crushers.

| Model | Output | Combination mode | Voltage | Heating mode | Material | Scope of application | Control mode |

| 100L | 100L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | SUS304/316L | Hotel、wine bar.restaurant etc. | Semi automatic / automatic |

| Three vessels brewhouse | |||||||

| 200L | 200L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 500L | 500L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 1000L | 1000L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| Remark | The above models can be customized according to the requirements | ||||||

We all know that the saccharification system has four steps: saccharification - Filtration - boiling - rotary sedimentation. It can be seen that the combination of saccharification system is also different. For beer equipment used in general bars, we use more combinations of two devices, mashing / boiling pot + lauter tun + whirlpool tun.

The fermentation system is mainly composed of fermentation tanks, and the number of fermentation tanks mainly depends on the batch produced every day. Beer fermentation is to convert the sugar of wort into ethanol and carbon dioxide through yeast metabolism, and form a series of fermentation by-products, such as alcohols. The fermentation products of these products determine the physical and chemical properties of beer such as flavor, foam, color and stability, giving the typical characteristics of beer. According to the traditional method, the beer fermentation process is divided into two stages: pre fermentation (also known as main fermentation) and post fermentation.

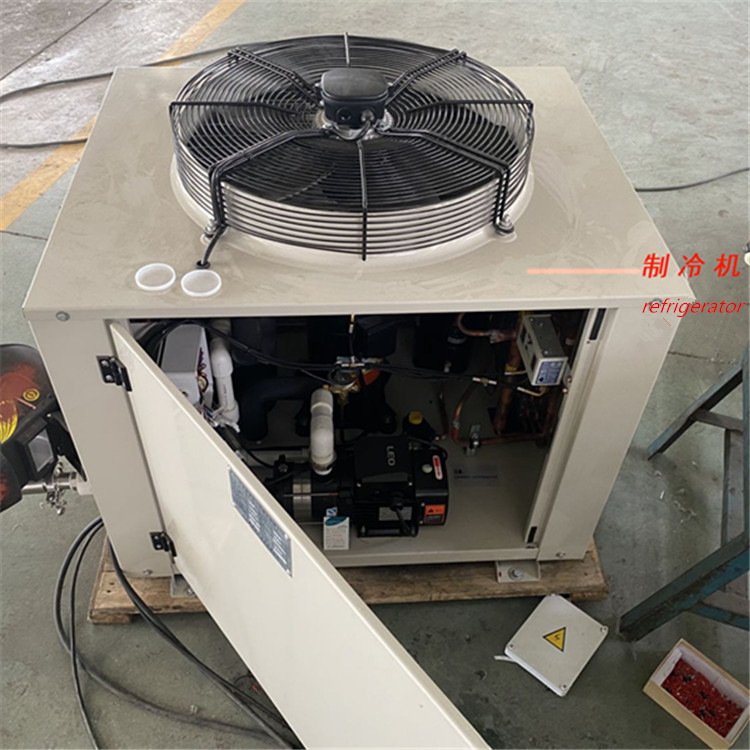

The main function of the refrigeration system is to provide a cold source for the cooling of wort and fermentation after swirling sedimentation. The main equipment consists of: ice water tank (add ethylene glycol or edible alcohol with 30% of the tank volume to ensure no freezing at minus 6 ℃), cold water tank (large equipment and multi batch brewing need to be equipped, small equipment can not be used) and refrigerator.

CIP cleaning system is mainly composed of CIP cleaning mobile trolley and pipeline. CIP cleaning tank is generally composed of alkali tank and disinfection tank. Bar beer equipment is generally cleaned and sterilized by in-situ cleaning method, that is, the process of cleaning and disinfecting the equipment without dismantling equipment parts or pipe fittings in a closed environment. The larger the equipment, the higher the requirements for cleaning the equipment. Configure CIP equipment according to equipment size and requirements.

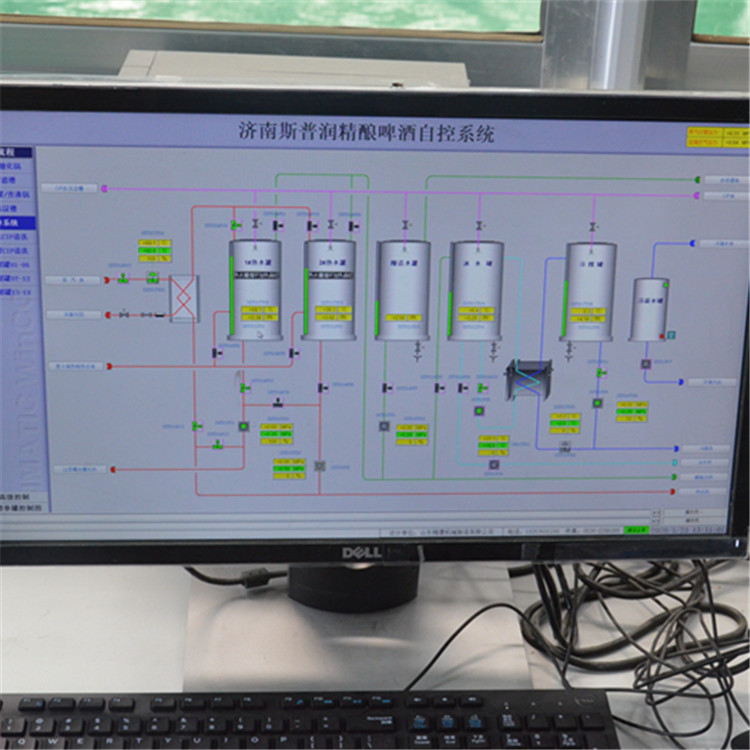

It mainly refers to the electronic control, semi-automatic and automatic control of each system. Control of saccharification system, fermentation system, refrigeration system, etc. The control of small equipment is relatively simple and the price is relatively cheap. Large equipment has high control requirements, high automation level and complexity, and high cost.

Filling equipment mainly refers to the subsequent treatment and packaging of the liquor after beer fermentation and maturation. Simple bottle filling machine, barrel filling machine and barrel washing machine; High automation bottle filling machine and can filling equipment. As well as filtration equipment, sterilization equipment (commonly used sterilization equipment: instant killing, Bazar, sterilization kettle), packaging equipment, etc. Large factories need high concentration dilution equipment, etc

If you want to ask anything just fill in the form below and send us.