Beer is people's favorite drink, especially now craft beer is more and more sought after by young people. Craft beer is emerging in more and more craft beer houses, bars, and restaurants. As a result, how to choose craft beer equipment and how to choose craft beer equipment manufacturers have become their consideration. Good beer cannot be separated from good craft beer equipment.

| 1 | Malt milling system | 1 | Malt milling machine |

| 2 | Mash system | 1 | Mash/kettle tun |

| 2 | Lauter/whirlpool tun | ||

| 3 | Hot liquor tank | ||

| 4 | Plate heat exchanger | ||

| 5 | Wort oxygenator | ||

| 6 | Yeast addition tank | ||

| 7 | Operation platform | ||

| 8 | Wort pump | ||

| 9 | Hot water pump | ||

| 3 | Fermentation system | 1 | Fermenter |

| 2 | Mixing tank | ||

| 3 | PRV | ||

| 4 | Vent valve | ||

| 4 | Cleaning system | 1 | Mobile cleaning cart |

| 5 | Cooling system | 1 | Chiller |

| 2 | Glycol water tank | ||

| 3 | Ice water pump | ||

| 6 | Electrical System | 1 | Fermentation auto control |

| 2 | Switchboard | ||

| 3 | Fermentation control solenoid valve | ||

| 4 | Temperature Sensor | ||

| 5 | Wire and Cable | ||

| 6 | Threading tube | ||

| 7 | Filling system | 1 | Bottle rinsing machine |

| 2 | Linear filling and capping machine | ||

| 3 | Linear sticker labeling machine | ||

| 4 | Conveyor system | ||

| 8 | Steam system | 1 | Electric steam boiler |

| 9 | Pipeline accessories | 1 | Mash, CIP, water pipeline |

| 2 | Glycol water pipeline | ||

| 3 | Steam pipeline | ||

| 4 | Air compression pipeline | ||

| 5 | Food grade hose | ||

| 6 | Other |

| Model | Output | Combination mode | Voltage | Heating mode | Material | Scope of application | Control mode |

| 100L | 100L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | SUS304/316L | Hotel、wine bar.restaurant etc. | Semi automatic / automatic |

| Three vessels brewhouse | |||||||

| 200L | 200L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 500L | 500L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 1000L | 1000L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| Remark | The above models can be customized according to the requirements | ||||||

Used in bars, restaurants and other places, the saccharification system generally uses indoor exhaust devices, which can discharge the secondary steam from the saccharification process and boiling process indoors, reducing environmental pollution caused by the direct emptying of the secondary steam, and it can also be used indoors. The discharged secondary steam is recovered as waste heat and converted into hot water for other uses, so as to achieve the purpose of energy saving. Using the indoor exhaust device can also make the saccharification space no steam or dripping water, and optimize the working environment.

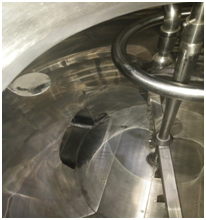

Filter tank ring-shaped washing pipe

When washing grains in small filter tanks, cleaning balls or double umbrella flow plates are usually used to wash grains. Since the cleaning balls or double umbrella flow plates are eccentrically arranged in the filter tank, the process of washing the grains will have a certain impact on the grains. The filtering speed and filtering quality are affected. After being changed to a ring-shaped washing pipe, the spent grains can be washed evenly, and the filtering speed and quality of filtered wort can be improved.

Filter trough wort collection pipe and sieve plate backwash pipe

The evenly distributed wort collection port and collection tube at the bottom of the filter tank can make the wort filter evenly, reduce the short-circuit phenomenon of wort caused by the unevenness of each part of the wort filter, and improve the filtering effect. The evenly distributed sieve plate at the bottom of the filter tank The flushing pipeline can flush the filter screen evenly, reduce pollution caused by improper flushing of the screen, improve the use effect of the filter tank, and ensure the quality of filtered wort.

The fermentation system is mainly composed of a fermentation tank, with a Miller plate jacket or a coiled tube jacket, and an 80mm insulation. The legs are welded with reinforcement plates to make the fermentation tank more durable. The bottom cone angle is 60°, which makes the yeast easier to sink and can be recycled.

If you want to ask anything just fill in the form below and send us.