Brewing beer at home is easy. This is a basic overview for brewing an extract beer recipe. Click here to learn about all-grain brewing.

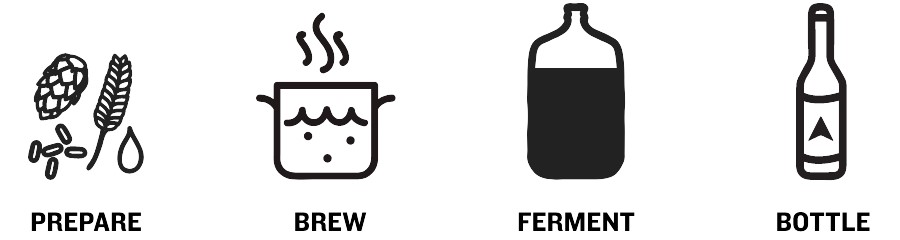

THE 4 BASIC STEPS:

1. Gather your brewing equipment. You'll need:

Brewing Kettle

Fermenter + Air Lock

Funnel (optional)

Sanitizer

Auto-Siphon

Stir Spoon

Beer Recipe Kit (or individual ingredients)

If gathering all of that sounds like too much work, simply choose one of Northern Brewer's beer making kit that have everything you need to brew beer, all in one box.

2. Sanitize, Sanitize, Sanitize. Your success will rely on how clean your equipment is. Anything that comes in contact with your beer after the boil process should be sanitized. PBW and Star San are great cleaners and santizers.

1. Add Grains. Fill your 5-gallon brew kettle with 2.5 gallons of water. As you heat your water, steep your grains for 20 minutes, or until your water reaches 170 degrees. When you remove your grains, let the water drip out of the grain bag and into the kettle. Don't squeeze your grain bag as you don't want to extract tannins, which may give your beer unwanted flavors.

2. Bring kettle to a boil - Once your kettle comes to a rolling boil remove it from heat and add malt extracts. Once the extract is dissolved return to a boil. Hops will now be added at various intervals. (Note: Be careful not to boil over when hops are added.) Refer to your exact recipe as to when you need to add hops to your boil.

3. You now have wort - Otherwise known as sugar water. Cool your wort as quickly as possible. This can be done one of two ways:

Ice Bath - Simply set your pot into a sink filled with ice water.

Use a wort chiller - Insert chiller into your wort. Run cold water from your tap through the chiller and out to the sink. A wort chiller is the most effective way, but either will get you the desired results.

Don't forget to sanitize all your supplies! Then...

1. Pour cooled wort into the fermenter. Some brew kettles even have a valve for easy transportation from your kettle to your fermenter.

2. Add water to bring the level to 5 gallons.

3. Aerate wort by splashing it around in its container. Yeast need oxygen, and splashing your wort will help.

4. Add yeast. Dry yeast is the easiest, as you don't have to prepare it beforehand. Sanitize the yeast pack + scissors, cut the corner off the yeast pack, and pour the yeast into the fermenter.

5. Seal your fermenter, add a fermentation air lock, and store in a dark cool place. Ales should stay at 68 degrees to ferment properly.

You did it. You made beer. All that's left to do this.

1. Refrigerate.

2. Enjoy.

The above are all done manually. During this brewing period, it is difficult to control temperature and pressure. The biggest difference between modern brewing technology and the past is that we can help solve the brewing process through a more automated system. The difficult problem enables brewers to focus more on the exploration of recipes and the development of new tastes of beer.

Is the beer we brewed according to the above steps draft beer or craft beer?

If you are new to the world of beer, you might come across the terms ‘craft’ and ‘draft’ to describe this crispy, frothy drink. But, are they the same thing? What’s the difference between craft vs draft beer? Read on, we’ll tell you everything you need to know about these two classifications.

Now that we know what craft beer and draft beer are as well as their respective history, let’s look at the difference between the two.

The truth is, there is actually no significant difference between craft and draft beer. Beer that has been crafted and produced by a small, independent brewery can be tap-drawn and this would then transform it into draft beer.

On the other hand, draft beer that is stored in kegs and drawn from taps can either be artisanal or just regular beer.

Craft beer is all the rage among younger, sophisticated drinkers who are after innovative and refined flavors, whether bottled, canned, or tapped. Draft beer does have a long history, but at its core, this is just beer that is well stored to protect it from the vagaries of light and oxygen.

In the end, artisanal beer can be tapped to make it a draft beer and draft beer comes in all styles and flavors as long as it is stored in a keg.

According to the above steps, different flavors of draft beer and craft beer can be brewed. How to brew beer is no longer a mystery. Raw beer and craft beer are different flavors of beer that we brew step by step. As long as you know how to make beer, you can set your own style in some different steps to make beer with unique flavor.

WEMAC is the professional beer brewing manufacturer ,Since its inception in 1958, WEMAC’s brewery division has been offering customized plants, equipment & technology solutions to customers in thebrewing industry,WEMAC supplies world class brewery plants capable of producing the best quality beers at the most optimum cost. The breweries are environment friendly, utilizing minimum water, energy and generating a low carbon footprint. With over 70% of market share in Europe and experience of installing projects in USA,WEMAC offers a complete range of solutionsin conceptualization, technology, design, plant engineering, project installation and commissioning.

The key to flavorful beer lies in the perfect harmony of all the systems in a brewery, and WEMAC offers the latest technologies and solutions in wort production, fermentationand filtration. Whether a greenfield or brownfield project, WEMAC offers seamless integration of engineering and technology services.

Commercial beer equipment is at the heart of the modern brewing industry. This article will look at 2000 liter commercial beer equipment, a moderately sized brewing system suitable for small to medium sized bars, restaurants and breweries. We'll learn about its key components, operational processes, and the business considerations associated with them.

More >>

Brewing system: The Restaurant Nano Brewery Equipment brewing system is the heart of any brewery, and a nano brewery is no exception. Restaurant Nano Brewery Equipment typically consists of a mash tun, brew kettle, and fermenter. The size of the brewing system will depend on the amount of beer you plan to brew, but for a restaurant nano brewery, a 1- or 2-barrel system is common.

More >>

Craft brewery equipment is widely used in medium breweries and beer pubs. It can brew pale lager, amber lager, dark lager, ale and etc at proper temperature with different raw material.

More >>668.jpg)

A complete set of 500L beer equipment consists of malt crushing system, saccharification system, fermentation system, steam system, refrigeration system, CIP cleaning system, pipeline system, etc. 500L brewing beer equipment is generally used in commercial, restaurants, bars, barbecue shops and other places.

More >>

100L beer equipment can be used in home brewing and business. Each batch can produce 100L beer, and two batches can be made every day, up to 200L beer. If you are at home, you can produce beer every few days. If it is commercial, first of all, it is necessary to determine how many liters of beer are produced a day. The 100L beer equipment can produce up to three batches a day, but considering the labor intensity, it can produce up to one or two batches a day. The number of fermentation tanks is determined according to the amount of beer produced.

More >>

Small beer equipment is generally divided into two types, one is small household simple equipment, and the other is commercial beer equipment. Small household simple equipment generally refers to 30l-100l, with small floor area, convenient operation and relatively simple technology. Commercial beer equipment generally refers to 300l-2000l beer equipment. Now the popular fine brewing beer equipment in the market is made with this equipment.

More >>

The 100L micro beer equipment belongs to a small beer brewing system. Small space, high degree of automation, simple and easy to operate. The mash process is electric heating, which is generally equipped with two device specifications (mashing+lautering + boiling+whirlpool), with ice water tank, plate heat exchanger, wort oxygenator, wort pump, etc; The fermentation process is automatically controlled by PLC, and 6 fermentation tanks are generally configured according to the standard. It belongs to self entertainment beer brewing equipment.

More >>

If you are planning to build a brewery, you must consider the turnkey beer project. What is the whole turnkey beer production line like? Which manufacturers can do a good job in this beer production line? What problems should we pay attention to? The beginning of a new project certainly requires a lot of preparatory work and a lot of problems. Many times, it is very difficult. This professional problem should be solved by a professional company. We can provide you with the turnkey work of the whole beer project, with more than 60 years of production experience.

More >>

As a popular drink, more and more people like to brew beer. How is beer brewed? According to beer concentration, it is divided into high concentration beer, medium concentration beer and low concentration beer. According to the production mode, it is divided into: fresh beer, pure draft beer and cooked beer. No matter what kind of beer, the beer brewing system is divided into: malt crushing system, saccharification system, fermentation system, CIP cleaning system, refrigeration system, control system, filling system and water treatment system.

More >>

As one of the oldest beverages in the world, beer has a history of 4000-5000 years. It uses malt as the main raw material, adds hops, and is brewed by yeast. Craft beer is actually an innovation movement in the beer industry. Behind it is the rise of the young consumers born in the 80s and 90s. They have higher requirements for consumer experience, personalization and diversification.

More >>

For beer equipment, each customer has different requirements. We have talked about what equipment beer equipment needs, how to choose beer equipment, and what is the most suitable scheme? According to the different needs of each customer, today we will talk about the additional configuration of beer equipment, so that we can use it better and more conveniently to brew higher quality beer.

More >>

As the core of the whole beer equipment, saccharification system is the key to brewing beer, so how to choose the saccharification system suitable for you? As we all know, the saccharification system is divided into four steps: saccharification - Filtration - boiling - spin sedimentation. In order to achieve the desired effect in each step and save cost, the combination of saccharification system is very key.

More >>