Inside surface: SUS304 wire drawing board, Thickness:3.0mm,Outside surface: polishing stainless steel, Thickness:2.0mm;

Thermal insulation material: Polyurethane (PU) foam, Insulation thickness: 80MM.

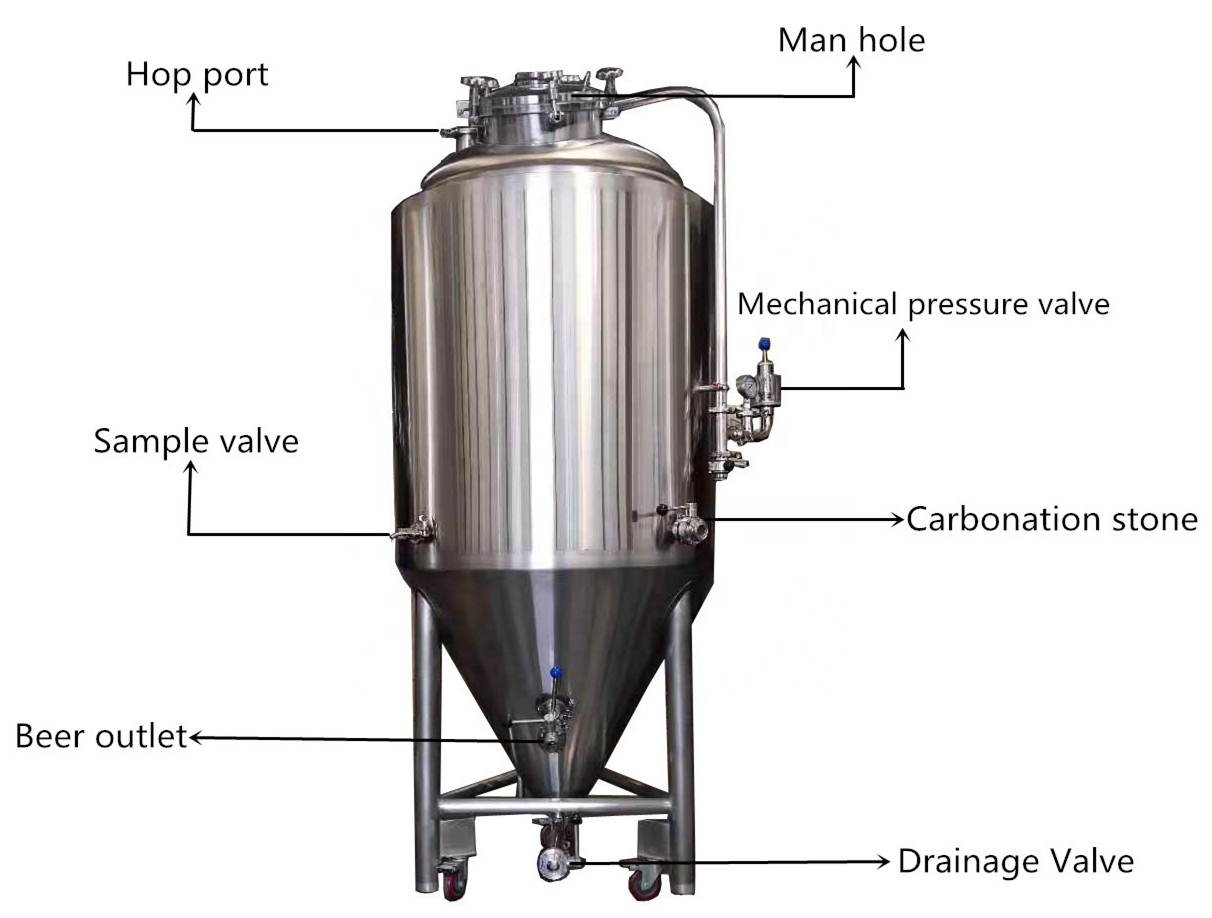

Manhole: Top manhole

Design pressure 3bar, Working pressure: 1.5bar;

Bottom design: 60degree cone for easy to exist yeast.

Cooling method: Dimple cooling jacket;

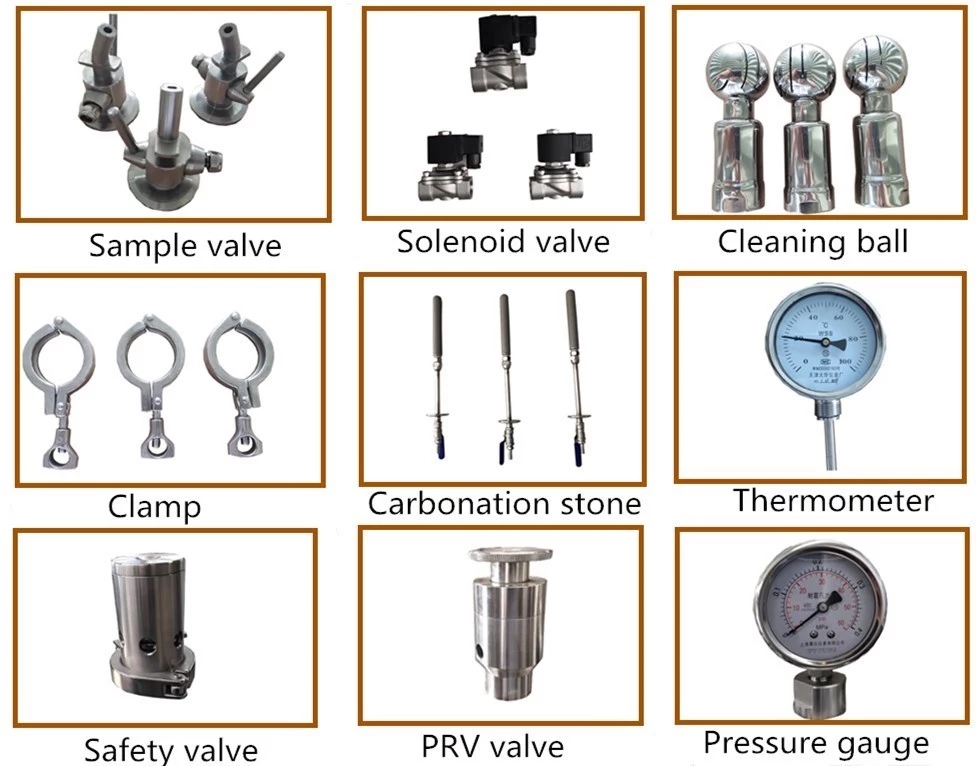

Cleaning system: Fixed-round rotary cleaning ball.

Control system: PT100, temperature control;

Brewery equipment 500L Fermenter

Fermentation tank:

Fermenter cooling method is cooling dribbling with standard parameters, layout and control mode in domestic. Zunhuang companies design and manufacture cooling dribbling according to 0.4-0.5 meters per cubic meter cooling area. And the fermentation tank adopt two-stage cooling refrigerant control mode at the end of the cone and the tank level 10--15cm down. So such design and cooling method to control the flow of the cooling liquid state in fermentation tank by the size of the two-stage cooling refrigerant flow. It will improve heat transfer efficiency and cooling rate, faster cooling, and reduce cooling costs and high economic efficiency equipment commercial operation.

Product details process:

Effective volume:500L

Inside surface: SUS304 wire drawing board, Thickness:3.0mm,Outside surface: polishing stainless steel, Thickness:2.0mm;

Thermal insulation material: Polyurethane (PU) foam, Insulation thickness: 80MM.

Manhole: Top manhole

Design pressure 3bar, Working pressure: 1.5bar;

Bottom design: 60degree cone for easy to exist yeast.

Cooling method: Dimple cooling jacket;

Cleaning system: Fixed-round rotary cleaning ball.

Control system: PT100, temperature control;

With: CIP arm with spray ball, pressure gauge, mechanical pressure regulating valve, sampling valve , breath valve, drain valve, HYPERLINK "app:ds:thermometer" thermometer, etc.

Surface protection, weld slinging band with stainless steel leg, adjustable bolt to adjust leg height;

Argon arc welding, Inside and outside the polishing, No welding corner to ensure the quality of the fluid.

Choose us for your advantages:

1. We have Professional personnel about the beer brewery, including, professional winemakers, professional engineers, professional drawers, professional marking specialists and professional installation personnel and service group.

2. We have much experience about the brewery design, manufacture, installation and service. We have sold many products to many countries and more and more companies from many countries will use our products to produce the beer and realize their brewery dream. We are glad to help those who want brew beer to realize their dreams.

3. We have far high effective teams; so that we could answer your questions more quickly, providing you our drawing for you, manufacturing your equipments in less time, saving your time and help you start to produce ahead of time.

4. We have professional service team; if you have any problems and suggestions about our product during the use procedure, please free to ask us and we are glad to solve your problems.

5. We could produce better products with a reasonable price. As we have low manpower resources and low and quality raw materials, so that you can own high quality products with a low price.

If you want to ask anything just fill in the form below and send us.