beer brewing equipment,configuration of beer brewing equipment,brewery equipment,configuration of beer machine

Optional additional configuration of beer brewing equipment-Indoor exhaust device

Indoor exhaust device of saccharification system

The secondary steam in the saccharification process and boiling process can be discharged indoors to reduce the environmental pollution caused by the direct emptying of the secondary steam and purify the indoor air. The waste heat of the secondary steam discharged indoors can also be recovered and converted into hot water for other use. The hot water can be put into the hot water tank for the next saccharification and washing of wheat grains, so as to achieve the purpose of saving energy. The indoor exhaust device can also make the saccharification space free of steam and dripping water, so as to optimize the working environment. Reduce the cost of discharge pipeline and save cost.

Optional additional configuration of beer brewing equipment-scape of indoor exhaust device

The indoor exhaust device of saccharification system is suitable for restaurants, bars and other places where the relative space is relatively sealed and the steam is not easy to be discharged.

Optional additional configuration of beer brewing equipment-Feed water mixer

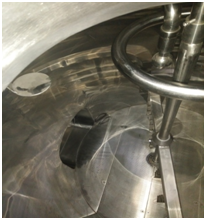

Feed water mixer of saccharification system

When the crushed malt powder falls into the saccharification pot, the slurry mixing water with automatic temperature adjustment is added into the mixing chamber according to a certain proportion. Through the material water distribution of the umbrella structure, the malt powder and slurry mixing water are evenly mixed, and then directly sent to the saccharification pot. The material liquid mixing ratio and slurry temperature meet the process requirements at one time, It can fully reduce the easy agglomeration of malt powder during feeding, reduce the material loss in the production process, and improve the uniformity and stability of saccharification operation.

Optional additional configuration of beer brewing equipment-Filter tank ring-shaped washing pipe

Filter tank ring-shaped washing pipe

When washing grains in small filter tanks, cleaning balls or double umbrella flow plates are usually used to wash grains. Since the cleaning balls or double umbrella flow plates are eccentrically arranged in the filter tank, the process of washing the grains will have a certain impact on the grains. The filtering speed and filtering quality are affected. After being changed to a ring-shaped washing pipe, the spent grains can be washed evenly, and the filtering speed and quality of filtered wort can be improved.

Optional additional configuration of beer brewing equipment-Filter trough wort collection pipe and sieve plate backwash pipe

Filter trough wort collection pipe and sieve plate backwash pipe

The evenly distributed wort collection port and collection tube at the bottom of the filter tank can make the wort filter evenly, reduce the short-circuit phenomenon of wort caused by the unevenness of each part of the wort filter, and improve the filtering effect. The evenly distributed sieve plate at the bottom of the filter tank The flushing pipeline can flush the filter screen evenly, reduce pollution caused by improper flushing of the screen, improve the use effect of the filter tank, and ensure the quality of filtered wort.

Commercial beer equipment is at the heart of the modern brewing industry. This article will look at 2000 liter commercial beer equipment, a moderately sized brewing system suitable for small to medium sized bars, restaurants and breweries. We'll learn about its key components, operational processes, and the business considerations associated with them.

More >>

Brewing system: The Restaurant Nano Brewery Equipment brewing system is the heart of any brewery, and a nano brewery is no exception. Restaurant Nano Brewery Equipment typically consists of a mash tun, brew kettle, and fermenter. The size of the brewing system will depend on the amount of beer you plan to brew, but for a restaurant nano brewery, a 1- or 2-barrel system is common.

More >>

Craft brewery equipment is widely used in medium breweries and beer pubs. It can brew pale lager, amber lager, dark lager, ale and etc at proper temperature with different raw material.

More >>668.jpg)

A complete set of 500L beer equipment consists of malt crushing system, saccharification system, fermentation system, steam system, refrigeration system, CIP cleaning system, pipeline system, etc. 500L brewing beer equipment is generally used in commercial, restaurants, bars, barbecue shops and other places.

More >>

100L beer equipment can be used in home brewing and business. Each batch can produce 100L beer, and two batches can be made every day, up to 200L beer. If you are at home, you can produce beer every few days. If it is commercial, first of all, it is necessary to determine how many liters of beer are produced a day. The 100L beer equipment can produce up to three batches a day, but considering the labor intensity, it can produce up to one or two batches a day. The number of fermentation tanks is determined according to the amount of beer produced.

More >>

Small beer equipment is generally divided into two types, one is small household simple equipment, and the other is commercial beer equipment. Small household simple equipment generally refers to 30l-100l, with small floor area, convenient operation and relatively simple technology. Commercial beer equipment generally refers to 300l-2000l beer equipment. Now the popular fine brewing beer equipment in the market is made with this equipment.

More >>

The 100L micro beer equipment belongs to a small beer brewing system. Small space, high degree of automation, simple and easy to operate. The mash process is electric heating, which is generally equipped with two device specifications (mashing+lautering + boiling+whirlpool), with ice water tank, plate heat exchanger, wort oxygenator, wort pump, etc; The fermentation process is automatically controlled by PLC, and 6 fermentation tanks are generally configured according to the standard. It belongs to self entertainment beer brewing equipment.

More >>

If you are planning to build a brewery, you must consider the turnkey beer project. What is the whole turnkey beer production line like? Which manufacturers can do a good job in this beer production line? What problems should we pay attention to? The beginning of a new project certainly requires a lot of preparatory work and a lot of problems. Many times, it is very difficult. This professional problem should be solved by a professional company. We can provide you with the turnkey work of the whole beer project, with more than 60 years of production experience.

More >>

As a popular drink, more and more people like to brew beer. How is beer brewed? According to beer concentration, it is divided into high concentration beer, medium concentration beer and low concentration beer. According to the production mode, it is divided into: fresh beer, pure draft beer and cooked beer. No matter what kind of beer, the beer brewing system is divided into: malt crushing system, saccharification system, fermentation system, CIP cleaning system, refrigeration system, control system, filling system and water treatment system.

More >>

As one of the oldest beverages in the world, beer has a history of 4000-5000 years. It uses malt as the main raw material, adds hops, and is brewed by yeast. Craft beer is actually an innovation movement in the beer industry. Behind it is the rise of the young consumers born in the 80s and 90s. They have higher requirements for consumer experience, personalization and diversification.

More >>

For beer equipment, each customer has different requirements. We have talked about what equipment beer equipment needs, how to choose beer equipment, and what is the most suitable scheme? According to the different needs of each customer, today we will talk about the additional configuration of beer equipment, so that we can use it better and more conveniently to brew higher quality beer.

More >>

As the core of the whole beer equipment, saccharification system is the key to brewing beer, so how to choose the saccharification system suitable for you? As we all know, the saccharification system is divided into four steps: saccharification - Filtration - boiling - spin sedimentation. In order to achieve the desired effect in each step and save cost, the combination of saccharification system is very key.

More >>