1. Basic product information:

Capacity: 20L

One Vessel: Mash &lauter tun

Heating method: by electricity

2.Product configuration:

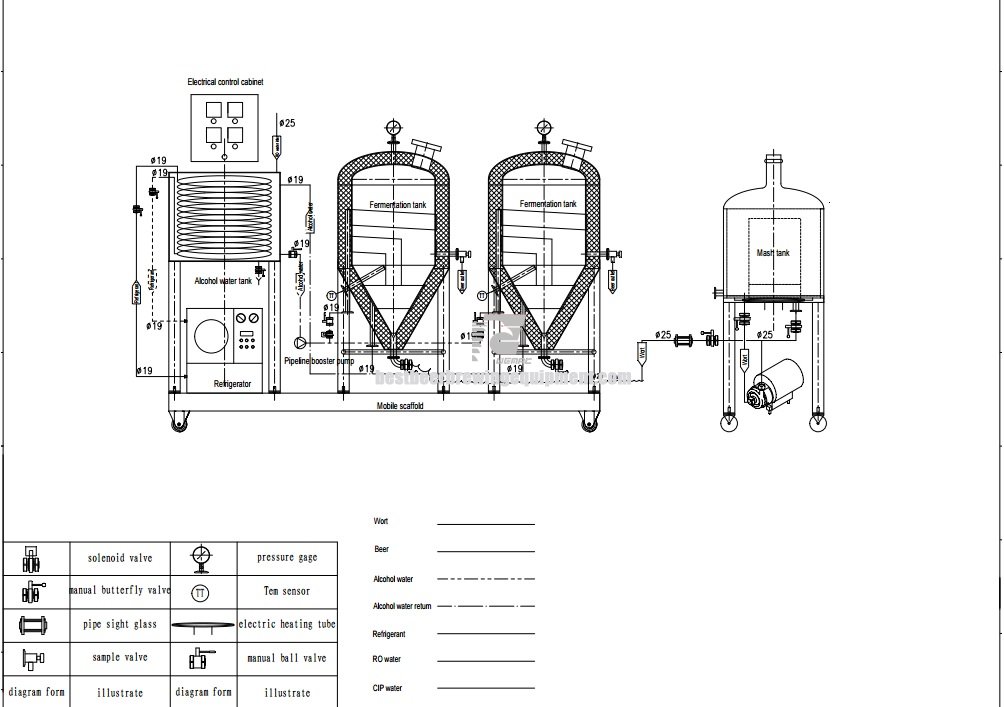

Mash system- Fermentation system- Cooling system-Piping system-Electric System

3.Detailed product configuration

3.1Mash system

3.1.1Mash & Lauter tun : Total volume is 40L, effective volume 30L .Material: inside and outside are all SUS304, the filter inside thickness: 1mm, outer barrel thickness:1.5mm. Upper equipped with mobile dished head, with steam outlet pipe, thickness is 2 mm. Filter form: through wort pump to filter, double filter plate. Heating method: electric heating tube. Temperature measurement methods: PT100 temperature sensor.

3.1.2Wort pump: Sanitary centrifugal pump, pump body and impeller material stainless steel 304, conform to the requirements of the health level of pump.370 w, lift 10 ~ 15 m. Granularity for 3 to 5 mm.

3.1.3The cooling coil: Match with mash tank, strictly calculate heat transfer. Made of health polishing pipe, the overall highly polished, not changeful form, easy clean. Supporting the hose connector, connection is simple, easy to operate.

3.1.4Support bow: Match with mash inner barrel, health, simple, easy to use.

3.1.5Inner barrel handle: Match with mash inner barrel, health, simple, easy to use.

3.2Fermentation system

3.2.1Fermentation tank: Total volume is 50L, the effective volume is 40L.Empty capacity is 20%.Material:inside and outside are all SUS304.Inner shell thickness is 2mm,Cladding thickness is 1.5mm.Upper with double insulation dished head, the thickness is 2 mm. The lower cone under 60 °compressive design. Cooling mode: inner barrel external, conical bottom external coil jacketed cooling. Heat preservation method: polyurethane foam, insulation thickness: 70 mm. Temperature measurement methods: PT100 temperature sensor; Equipped with negative pressure valve, diaphragm pressure gauge, oxygen filling ball valves, sight glasses.Side with health sampling liquor valve. The bottom with cooling water solenoid valve, feed valve.

3.3Cooling system

3.3.1 The cooling water tank: Total volume is 50L, the effective volume is 40L.Material: inside and outside are all SUS304 Inner shell thickness is 2mm,Cladding thickness is 1.5mm.Upper with double insulated flat cover, the thickness is 1.5 mm; Insulation thickness is 60 mm.

3.3.2 Cooling way: inner barrel internal titanium cooling coil to cool. Heat preservation method: polyurethane foam, insulation thickness 70 mm; Temperature measurement methods: PT100 temperature sensor; Equipped with negative pressure valve, diaphragm pressure gauge, oxygen filling ball valves, sight glasses, Drain valve at the bottom.

3.3.3Refrigerator:22Medium: freon 22

3.3.4Titanium evaporator:Made of titanium, healthy, no dead Angle. Evaporation area is large.

3.3.5Mobile scaffold:Integrated design for fixed mash tank, cold water tank, fermentation tank, electric control cabinet and pump, etc. Made of sanitary pipe, with handrails, high-quality universal wheel, etc. According to the customer site layout design

3.3.6Piping system:Including pipeline pump, piping system, quickly mounted manual butterfly valve, fast-assembly glass sight pipes

3.4Electric System

3.4.1Automation control cabinet: According to different beer can set different fermentation curve, to meet different fermentation technology. Achieve 2-24 hours any cooling speed setting, thereby preventing ice tank and protect the function of the yeast, and meet the normal fermentation mechanism .Temperature, time and cycle can be arbitrarily set and modified, System capacity meet a fermentation period. System once every 20 minutes collect data and summary, record all data of a fermentation cycle.

4.Flow diagram

If you want to ask anything just fill in the form below and send us.