When you want to be a restaurant, bar or barbecue shop and need to serve refined beer to attract customers, there will be a lot of preparation. First of all, brewing technology is necessary, and a process suitable for local taste is essential. Secondly, beer equipment must be considered. To brew good beer, a suitable equipment with high quality and low price will also be necessary. How to find a good device? Do not know this manufacturer, so many mixed manufacturers, which one to choose? Which model does the beer equipment use? If you choose the large one, the daily output will not reach, resulting in a waste of resources. If you choose the small one, the daily output will be too small to meet the daily demand.

How to choose a suitable 500L brewing system? As a professional beer equipment manufacturer, we must think from the perspective of customers and what kind of equipment customers are suitable for. What is the customer's site and how to get the pipeline to make it most convenient for the customer. The daily output of customers depends on how to configure and design according to the output, which can save money and make it more convenient for customers to use. Therefore, we cannot do without communication. We should constantly strengthen communication, solve fundamental problems and truly achieve win-win cooperation. The following is the 500L beer brewing system introduced.

Malt milling system

| Malt milling system | 1 | Malt milling machine | 200Kg/h | 1 | 1. Type: counter roll type 2. Material: stainless steel 3. Voltage 400V, 3Ph, 50Hz, 1.1kw 4. Speed of fast roll: 700 rpm 5. Overall dimension (h * L * WMM): 1365 * 780 * 600 6. The total weight is about 150kg. |

The first step is the malt crushing system. Generally, we recommend to use the counter roll malt crusher, which can better ensure that the inner core of malt is crushed completely, the outer skin is broken but not broken, and the wheat skin forms a natural filter layer to improve the filtration efficiency.

Mash system

| 2 | Mash system | 1 | Mash/kettle tun | Effective volume500L | 1 | WEMAC | 1. The inner tank is made of SUS304, 3mm, and the outer material is 2mm thick; Overall dimension: D = 1260mm, H = 2660mm |

| 2. Steam heating; Coil jacket, pressure resistance 3bar. Heating shall meet the temperature rise of 1-1.5 ° C / min; | |||||||

| 3. Thermal insulation rock wool, with a compacted thickness of 80mm. | |||||||

| 4. The air capacity is more than 40%. | |||||||

| 5. The speed of the mixing motor is 30R / min, the mixer in the tank is made of stainless steel 304, and the lower part of the mixing shaft is supported with a shaft sleeve. The upper part of the pot body is sealed to prevent steam leakage from the shaft operation.。 | |||||||

| 6. The diameter of the upper steam discharge pipe is ¢ 159. A condensate collection device is added on the steam discharge pipe, and the drainage pipe is embedded in the insulation layer. | |||||||

| 7. Bottom feed; | |||||||

| 8. Temperature sensor, - 10 -- 150 ℃, 4-20mA signal, l = 200mm, 50.5 chuck connection, brand Fred. | |||||||

| 9. 2B surface inside the equipment, pickling and passivation treatment, fine treatment of welds, no concave convex deformation, etc; The external surface is subject to wire drawing treatment, the appearance of the equipment is beautiful, and the pipeline layout and opening position meet the requirements of operation, on-site installation and visit. | |||||||

| 10. Round glass manhole, butterfly head | |||||||

| 11. Equipped with cleaning pipe, with standard cleaning ball and cleaning pipeline iso32. | |||||||

| 12. Optional: multi nozzle steam condensing device | |||||||

| 2 | Lauter/whirlpool tun | Effective volume500L | 1 | WEMAC | 1、The effective volume of the lauter tun is 500L,and the effective volume of the whirlpool tun is 500L | ||

| 2、The material of the inner tank is SUS304,thickness3mm、and the outer cover is 2mm;the external dimension:D=1160mm,H=2660mm. | |||||||

| 3、Rock wool insulation for filtering pare,thickness80㎜; | |||||||

| 4、There are 2 inlet pipes on the upper part,one of which is used for reflux and the other is used for wanshing the grains.The internal grain washing device adopts the form of double umbrella flow plate,and its three washing pipes are used for washing the filter tank,equipped with standard washing ball ISO32. | |||||||

| 5、The filter has a round manhole on the upper part and a square outlet on the side (with a chute for the outlet),the filter discharge header is equipped with a trial mirror and a sanitary sampling valve,and the sight glass is installed horizontally, the filter can realize natural filtration and suction filtration,and natural filtration.It can be washed at the same time. | |||||||

| 6、False bottom:milling.Made of SUS304,the opening rate is about 10%;the surface is bright and flat,the part can be opened,easy to clean,and it is not deformed,the distance between the filter plate and the bottom of thepot is between 2-5cm,and the bottom of the tank is equipped with a bottom cleaning device .uniformly distributed no less than 3. | |||||||

| 7.Rake device: the overall material is stainless steel 304; the installation and support are firm, and the rotation is stable; the speed is controlled by frequency conversion; the inclination angle of the tillage knife is ≤15°; the internal tillage tool holder is fixed on the cylinder of the tank, not the bottom; the stirring motor and The gearbox has a stainless steel 304 shield. Motor and gearbox speed 19r/min, select domestic well-known brands; | |||||||

| 8. Rotary counterclockwise tangential feeding, the feeding port is 1/3 below the liquid level; it has a liquid level tube, a breathing hole, and a quick-installation manhole on the side. The shape of the bottom and the discharging material not only ensure the spin-sinking effect, but also improve the convenience of operation and reduce the loss of material and liquid. There is a bypass between the suspension discharge pipe and the sewage pipe; Teflon liquid level pipe. | |||||||

| 9. The internal 2B surface of the equipment is pickled and passivated, and the welds have been finely processed, so there is no unevenness and deformation. | |||||||

| 10. The whirlpool tun is equipped with a cleaning tube, with a standard cleaning ball, and the cleaning pipeline is ISO32. | |||||||

| 3 | Hot liquor tank | Effective volume500L | 1 | WEMAC | 1.the inner liner is made of SUS304,the thickness is 3mm,and the outer material is 2mm thick;overall dimensions:D=960mm,H=2200mm 2.Rock wool,thermal insulation laminate with a solid thickness of 80mm 3.Conical head at the top,round manhole for installation,and conical head at the bottom. 4.Equipped with cleaning pipe,with standard ball cleaning,cleaning pipe ISO32,overflow port. | ||

| 4 | Plate heat exchanger | 1 | 1. Suspended. Design pressure 1.0MPa, design temperature 150 ℃; Flow 1t / h. 2. The plate and frame are made of 304 stainless steel. 3. The heat exchange area and process combination meet the following requirements: the wort is reduced from 98 degrees to 8-10 degrees, and the material is finished in 40 minutes. Water rises from 2 degrees to more than 80 degrees; Cooling water temperature - 5 ℃. 4. Both wort inlet and cold water inlet use ball valve to control flow, and wort temperature uses digital thermometer. | ||||

| 5 | Hop filter | 1 | WEMAC | 1. Valve plate material: SUS304; 2. Connection mode: quick installation; 3. Filtering accuracy: 40 mesh; 4. Applicable temperature: - 20-130 ℃; 5. Pressure range: 0-10bar. | |||

| 6 | Wort oxygenator | 1 | WEMAC | Venturi principle is made of SUS304, oxygenation is uniform and meticulous, with glass sight glass, oxygenation can be seen. | |||

| 7 | Operation platform and step | 1 | WEMAC | Stainless steel 304, anti sliding plate and guardrail. | |||

| 8 | Hot water pump | 1 | 1. The pump body and impeller are made of SUS304 high-quality stainless steel, which meets the requirements of sanitary pumps and is a well-known domestic brand. 2. The flow is 3 tons/hour, and the head is 18 meters | ||||

| 9 | Wort pump | 1 | 1. The pump body and impeller are made of SUS304 high-quality stainless steel, which meets the requirements of sanitary pumps and is a well-known domestic brand. 2. Frequency conversion control, with a flow rate of 3 tons/hour and a head of 24 meters. |

The above configuration is made according to the mash system of two bodies and three devices. The mash system has one device, two bodies and two devices, three bodies and three devices, four bodies and four devices, five bodies and five devices, etc. you can choose. The mash system is determined according to your usage habits, work efficiency and daily output.

Fermentation system

| Fermentation system | 1 | Fermenter | 500L | 6 | WEMAC | 1、The inner tank is made of SUS304,thickness 3mm,outsourcing is made of SUS304,thickness2mm,dimensions:D=1060mm,H=2260mm/Opening height of equipment manhole2530mm。 |

| 2、Miler board jacket,material SUS304,thickness 1.5mm,the cooling area of the cylinder is about 40% of the surface of the cylinder,and the cooling area of the cone is about 50% of the surfae of the cone. | ||||||

| 3、Polyrethane foam insulation,thickness 80mm。 | ||||||

| 4、The tank can withstand a pressure of2.5bar。 | ||||||

| 5、Compression resistant design of cone under 60° | ||||||

| 6、20%empty capacity.The upper part of the cylinder of the tank is flush with the bottom of the washing ball. | ||||||

| 7、Equipped with a washing ball, the installation position is slightly lower than the welding seam between the cylinder and the head, and the washing pipe is Ø32. | ||||||

| 8、The internal roughness is less than or equal to 0.4um, and there is no deformation, no scratches, and the welding seam is 2B surface. | ||||||

| 9、The upper part is equipped with manhole and positive and negative pressure safety valve, single head. | ||||||

| 10、The tank body is equipped with temperature sensor (-10--150℃, 4-20mA signal, L=200mm, 50.5 chuck connection, brand Forex), sampling valve; there is a sewage outlet at the bottom, and a wine valve at the bottom of the cone , DN100 for dried hops. | ||||||

| 11、The bottom drain pipe Ø38. | ||||||

| 12、The internal 2B surface of the equipment, pickling passivation treatment, external surface drawing treatment, beautiful appearance, pipeline layout, opening position, etc. meet the requirements of operation, on-site installation and visit. | ||||||

| 2 | BBT | 500L | 6 | The same as fermentation tank (without hops). | ||

| 3 | PRV | 12 | Material SUS304, mechanical pressure regulation, control the pressure in the fermentation tank, model WH-5101A (0.2-2.2bar), with flush diaphragm pressure gauge. | |||

| 4 | Vent valve | 12 | Material:SUS304 Installation:quick installation,chuck50.5 Pressure:0.2MPa | |||

| 5 | Mobile cleaningcart | 1 | WEMAC | 1、1 mobile cleaning pump,wiith control panel。 2、The cleaning pump flow is 2T/H,the head is more 20 meter,Corrosion resistance. |

The number of fermentation tanks is determined according to the batch produced every day and the type of beer. Moreover, we have made reinforcing plates for the legs of each fermentation tank, which is more solid and durable.

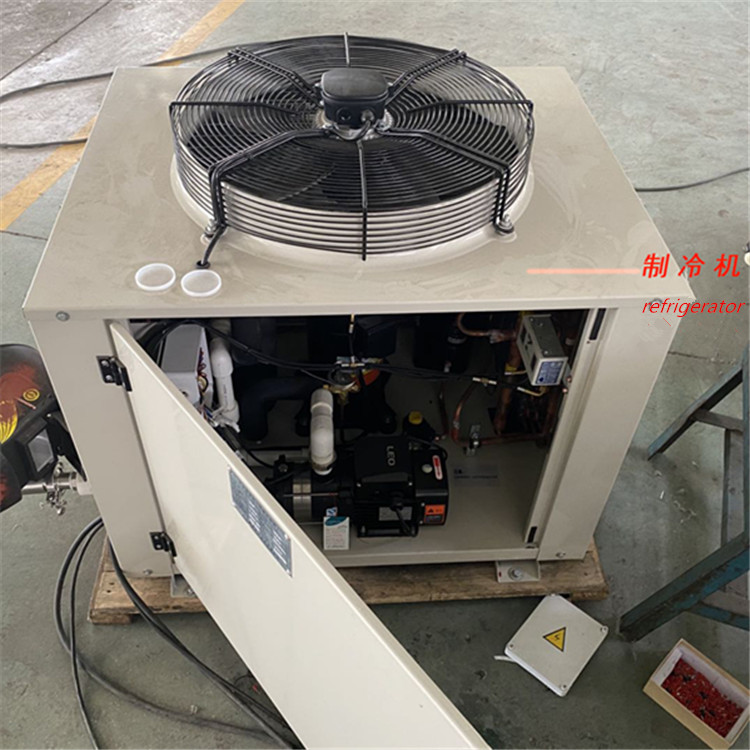

Cooling system

| Cooling system | 1 | Chiller | 5P | 1 | 1. Unit type: air-cooled chiller (glycol), voltage level 230V/400V 50Hz, total input power 4.86KW. 2. The capacity meets the requirements, the outlet water temperature is -5°C, and the nominal cooling capacity is 7.4KW. 3. Dimensions (L*W*Hmm): 1140*560*1040 4. Outdoor installation, ambient temperature <35℃. 5. Compressor: fully enclosed scroll type, refrigerant R22C. | |

| 2 | Alcohol tank | 1500L | 1 | WEMAC | 1. Liner material SUS304, 2mm, outer material thickness 1.5mm; Overall dimension: D = 1300mm, H = 2300mm 2. Polyurethane foam insulation 100mm. 3. Automatic temperature control. 4. Supporting valves and pipe fittings, and all pipelines shall be insulated | |

| 3 | Alcohol pump | Flow rate 3T/H,the head is 30M | 1台 | Alcohol water circulation pump, the capacity meets the requirements. |

The above configuration is for reference only. The most suitable scheme should be made according to your actual situation. If you have any questions, please contact us in time. Please leave your email, telephone and company name, and we will contact you immediately.

If you want to ask anything just fill in the form below and send us.