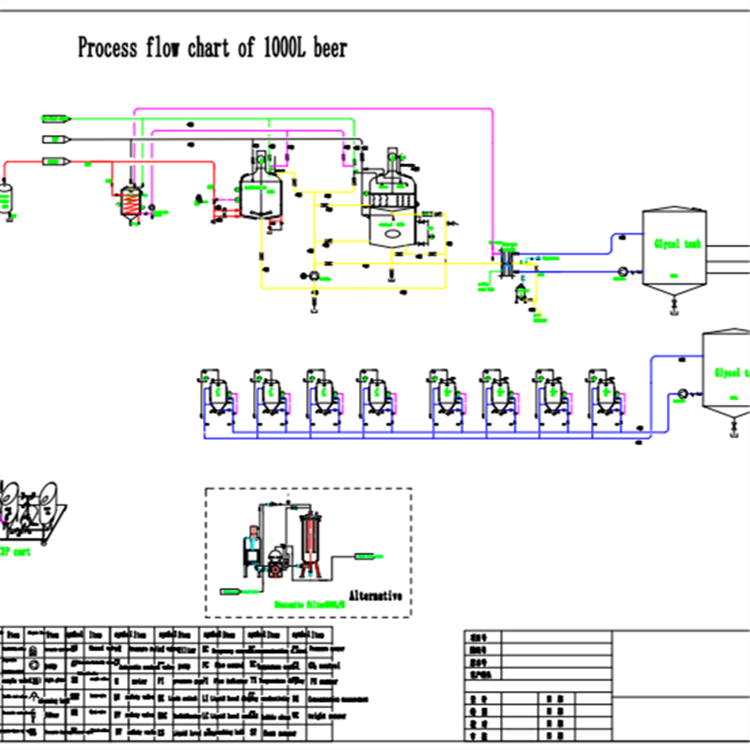

1000L fine brewing beer equipment is generally used in bars, hotels, high-end restaurants and other places, which is conducive to improving brand awareness and the grade of restaurants. It is a way to attract customers. 1000L brewing beer system includes malt crushing system, saccharification system, fermentation system, control system, refrigeration system, steam system, etc.

Wemac, the top 20 craft brewery equipment, has more than 60 years of production experience in beer equipment manufacturing. It has served fine brewing beer manufacturers all over the world and undertaken turnkey projects such as site planning, mechanical design, manufacturing and installation.

The above parameters are for reference only. If you want a 1000L beer system, please leave your contact information or send us an email to leave your requirements, and our engineers will customize it for you.

Malt crushing system is mainly composed of malt crusher, malt storage and feeding equipment. Small equipment can only be equipped with malt crusher. Small and medium-sized beer equipment is generally equipped with a pair of rod crushers, and large equipment is equipped with a four roll or five roll crusher of Shandong Jingying Machinery Manufacturing Co., Ltd. Crushing can be divided into dry powder and wet powder. Small and medium-sized beer equipment is generally dry powder. Malt is crushed for better dissolution. The malt is broken but not broken, and the wheat peel acts as a filter for wort filtration.

| Model | Output | Combination mode | Voltage | Heating mode | Material | Scope of application | Control mode |

| 100L | 100L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | SUS304/316L | Hotel、wine bar.restaurant etc. | Semi automatic / automatic |

| Three vessels brewhouse | |||||||

| 200L | 200L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 500L | 500L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| 1000L | 1000L/batch | Two vessels brewhouse | 380V/220V | by steam,by electricity,by fire | Hotel、wine bar.restaurant etc. | ||

| Three vessels brewhouse | |||||||

| Remark | The above models can be customized according to the requirements | ||||||

The above table parameters are the combination of saccharification system. To make beer, the saccharification system is inseparable from the four steps of saccharification - Filtration - boiling - rotary sedimentation. Therefore, the combination mode of saccharification system is also different, including two device combination, three device combination, four device combination, five device combination, etc. the combination mode of saccharification system is mainly determined according to the customer's output and customer's habits.

Let's focus on the combination of two devices. This saccharification combination is most used in 1000L fine brewing beer equipment.

Two tanks and three vessels mashing (mash tun+ lauter tun + boiling /whirlpool tun)

Saccharification system is the core of the whole beer brewing process. Saccharification includes one-step saccharification or multi-step saccharification. Different types of beer have different saccharification processes. The one-step saccharification method is to open the saccharification pot for stirring, add 65 ° - 70 ° water into the saccharification pot, slowly add the crushed malt into the saccharification pot, continue stirring and soak for about an hour.

The multi-step saccharification method is soaked in 37 ° water for half an hour to decompose the organic acids in the wort. The saccharification pot is required to increase 1 ° - 1.5 ° to 45 ° per minute, so that the protease can be moderately decomposed. Rise to 65 ° for saccharification, rise to 70 °, starch dextrin, which is the colloidal substance of beer, and finally rise to 78 °, inactivate the enzyme and end saccharification.

The above saccharification process is for reference only, and different beer saccharification processes are also different. If you have any questions, please contact us, and we will put forward reasonable suggestions according to your process.

After saccharification, the mash is pumped into the filter tank or filter press for filtration. The filter tank is provided with a sieve plate to filter the wort. The clear wort is put into the boiling pot, and the wheat grains are left in the filter tank.

The main purpose of boiling is to solidify protein and clarify wort; Sterilization, dissolution of hops, volatilization of undesirable substances and taste.

After wort boiling, the thermal condensate, condensate and hops grains in wort shall be effectively separated as soon as possible to obtain clarified wort. Wort is boiled and pumped into a rotary sedimentation tank, or self circulated in a boiling cyclone sedimentation pot; Distiller's grains and thermal condensate were separated for cyclotron precipitation.

Beer fermentation is a complex biochemical and material transformation process. The main metabolites of yeast are ethanol and carbon dioxide, and a series of fermentation by-products, such as alcohols, are formed at the same time. The fermentation products of these products determine the physical and chemical properties of beer such as flavor, foam, color and stability, giving the typical characteristics of beer. According to the traditional method, the beer fermentation process is divided into two stages: pre fermentation (also known as main fermentation) and post fermentation

The above characteristics of craft beer are required by the top 20 craft beer equipment. We strive for perfection in every detail to make it more convenient for customers to use. We will design the most suitable equipment for customers according to the specific requirements of customers.

If you want to ask anything just fill in the form below and send us.