Nano beer equipment is also micro beer equipment. The whole set of equipment is composed of crushing system, saccharification system, fermentation system, refrigeration system, etc. Suitable for home use, laboratory use, and small restaurant use. Restaurant nano beer equipment is used to produce fresh beer and filtered beer. This beer equipment is usually placed in places where consumers drink directly, such as restaurants, pubs, tourism and shopping centers. The appearance of the equipment is made of stainless steel, brass or copper, which improves the restaurant's grade and is more conducive to attracting customers.

The whole set of 50L nano brewery equipment consists of malt milling system, mashing system, fermentation system, cooling system, control system, CIP system, etc.

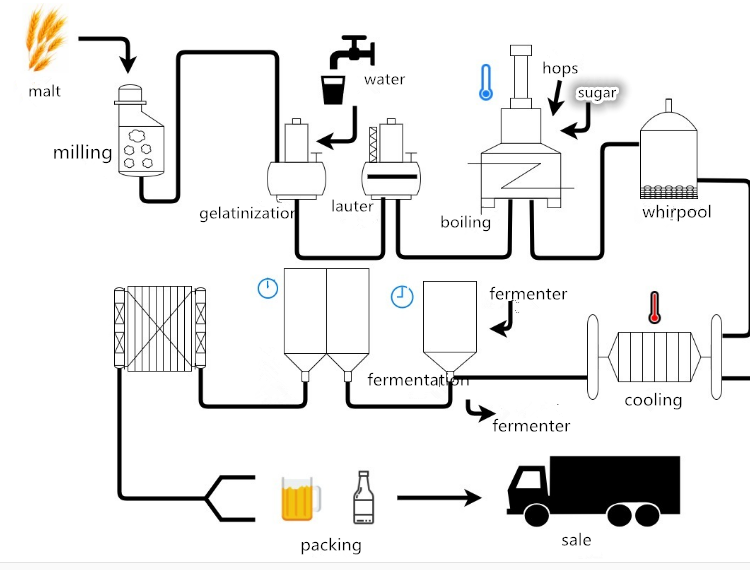

This is the whole brewing process.

We know that the saccharification system, like the heart of the human body, is the core of the whole brewing process. The whole saccharification process is saccharification - Filtration - boiling - whirlpool. Any beer brewing is inseparable from these four steps. The all-in-one machine is to complete the four brewing process steps of saccharification, filtration, boiling and rotary sedimentation of the whole saccharification system with one tank. It is divided into two layers: upper saccharification and filtration, lower boiling and rotary sedimentation. It is suitable for places with small output and limited space.

Among the 50L nano brewery equipment, the two vessel mashing system are commonly used. The saccharification, filtration, cooling and fermentation in the brewing process are independent equipment, which makes it easier to control the quality of wine and ensure the stability of taste.

As can be seen from the above figure, saccharification and rotary sedimentation are one pot, filtration and boiling are one pot, saccharification and filtration are one pot, boiling and rotary sedimentation are one pot, which depends on your usage habits.

This is the grain outlet. After the wheat grains are filtered, the wheat grains are discharged from here. The filter plate adopts a milled sieve plate with small gap above and large gap below, which is conducive to the normal filtration.

There is a glass sight on the bottom pipe, which can clearly see whether the wort is cool in the process of filtration and reflux, and carry out the next boiling operation.

If you want to ask anything just fill in the form below and send us.