Beer is a popular beverage, and there are many brewing beer lovers. First of all, hobbies are the best teacher and the greatest motivation. So in the next step, you will definitely look for what equipment is needed to brew beer? The whole set of beer equipment mainly includes malt crushing system, saccharification system, fermentation system, cleaning system, refrigeration system, electrical system, filling system, etc. It is mainly used in bars, restaurants, hotels, barbecue shops, craft beer houses, etc., which helps Upgrading the store has become a new kind of publicity, allowing consumers to see the beer brewing process more intuitively, and increasing consumer interest.

Craft beer is a small and refined type of beer that is fermented with water, malt, hops, and yeast without adding any preservatives. It is loved by young people because of its diverse taste. To brew a good beer, you must have good craft beer equipment.

Malt milling machine needed to sell craft beer

Malt crushing is the first step. The 500L-2000L medium-sized brewing equipment generally uses a pair of roller mills, which can break the malt skin without breaking, and obtain a reasonable degree of crushing of the malt. It is more conducive to the next step of saccharification and filtration. Try to complete the malt crushing within half an hour before saccharification to prevent oxidation of the malt powder caused by too long time.

Mash equipment needed to sell craft beer

The saccharification system is the core of the entire brewing equipment. The saccharification of any beer is completed by four steps, namely saccharification-filtration-boiling-spin sedimentation. Therefore, the saccharification system can be combined in various ways, including two combinations, three combinations, four Device combination, five device combination, etc. According to the daily output, different usage habits, and different combinations, today we will mainly talk about the two most commonly used combinations, namely the two-device combination.

Option 1: Saccharification/filter pot + boiling/revolving sinking pot

Option two: saccharification/boiling pot + filter pot + rotary sinking pot

The process of saccharification: water and malt crushing materials are fully mixed, and the soluble substances in the malt are thoroughly leached under the action of various enzymes of the malt. The crushed malt and water are mixed and called mash.

Fermentation system needed to sell craft beer

The fermentation system is mainly composed of fermentation tanks, which are used to store beer, that is, to ferment beer. Beer becomes beer after about 12 days of fermentation in the fermentation tank. Of course, different yeasts, different beer fermentation days It is also different. The fermentation tank has the functions of heat preservation and cooling. The control system controls the fermentation temperature of the fermentation tank, and the refrigeration system is the cooling medium for the fermentation tank. The fermentation tank constitutes an inner tank, a coil jacket or a Miller plate jacket, an insulation layer and an outer shell. The number of fermentation tanks is determined by the daily output. If the market positioning is not clear, you can first install 6 fermentation tanks, and then expand the production and then add more fermentation tanks.

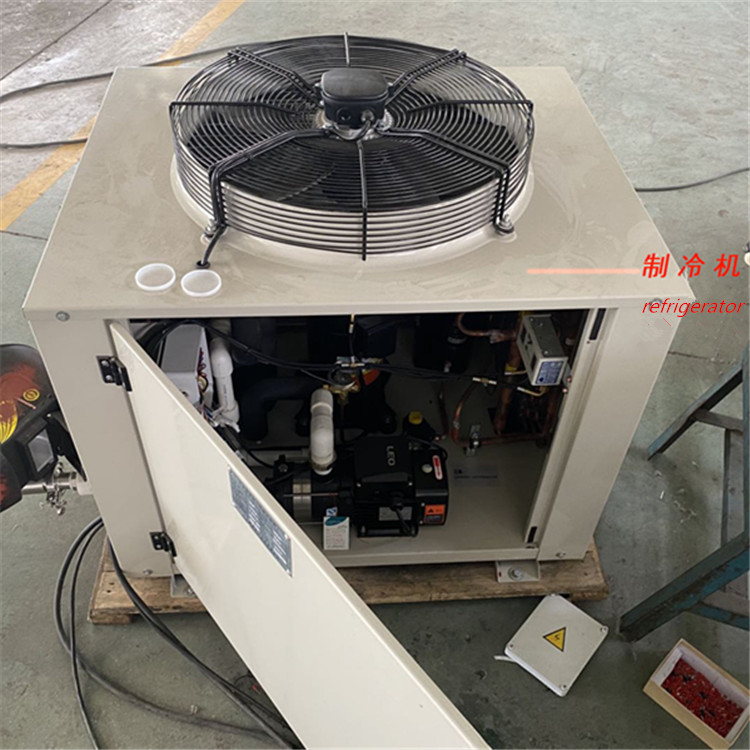

Cooling system needed to sell craft beer

The refrigeration system is mainly composed of a refrigerator, an ice water tank, a cold water tank, and an ice water pump. The ice water tank is added with ethylene glycol or edible alcohol, and the temperature can reach -6° without freezing. It is mainly used for the fermentation tank To cool down, you also need to cool down the cold water tank and keep the cold water tank at about 5°. The cold water tank is mainly used to cool down the wort after the rotation. Small equipment does not require cold water tanks. Cold water tanks are suitable for breweries with large output and large batches of production every day.

Cleaning system needed to sell craft beer

The cleaning system is mainly composed of a mobile cleaning vehicle, equipped with acid and alkali tanks, clean water tanks, and cleaning pumps. If it is a large-scale equipment, it needs to be equipped with a cleaning station, if it is a small-scale equipment, it is not necessary.

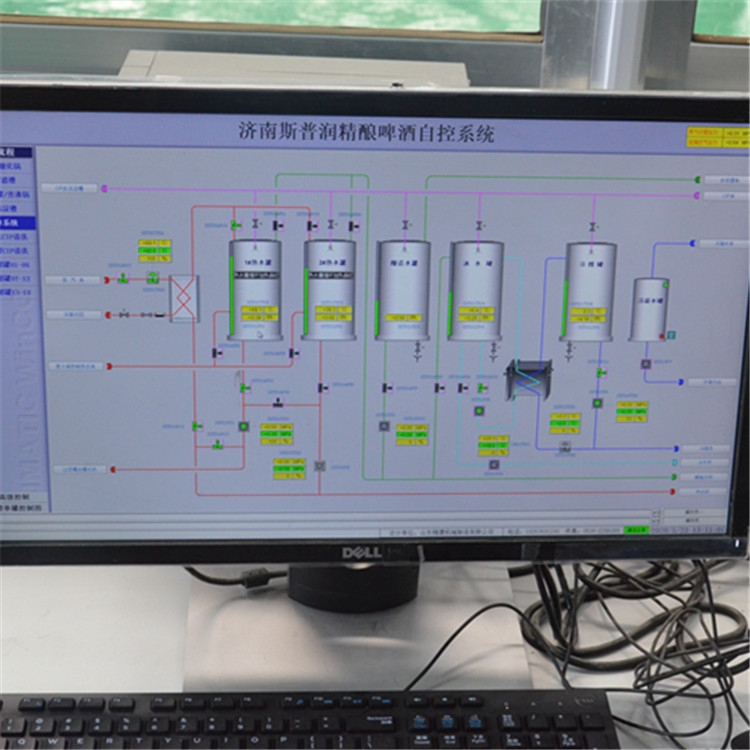

Electrical system needed to sell craft beer

The electrical system is mainly composed of fermentation autocontrol、switchboard、fermentation control solenoid valve、temperature sensor、wire and cable、threading tube.The control system is divided into manual, semi-automatic and fully automatic.

If you plan to use a set of beer equipment, and if there is anything else you don’t understand, please contact us as soon as possible. We will design a set of beer equipment suitable for you according to your requirements.

If you want to ask anything just fill in the form below and send us.