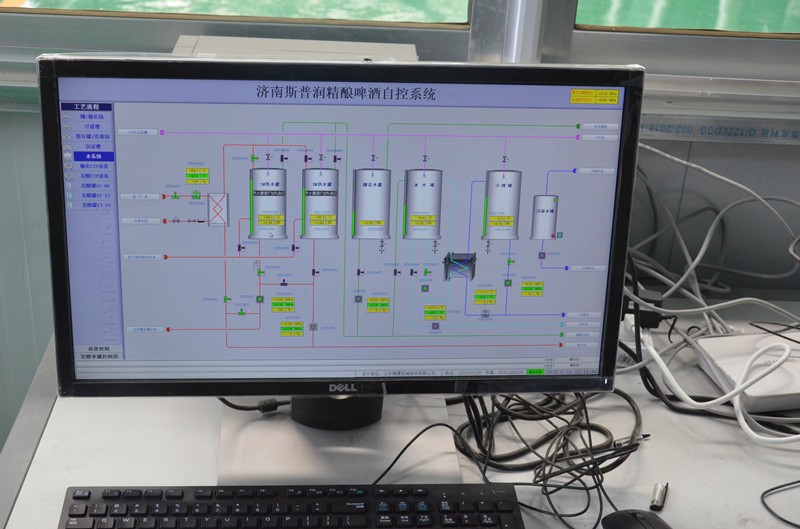

The automatic monitoring and control system is like the brain of the beermaking system, which can grasp the various processes of beermaking in real time.

After networking, the status of each process of beer brewing can be monitored online, and the heating temperature and time can be set according to different types of beer and brewing methods

The valves and pipelines identified in the picture are all programmed according to the actual layout of the site, and the temperature and time are updated in real time, and the error is within ±0.1℃.

The display range includes hot water tanks, cold water tanks, brewing water pipes, refrigerant tanks, etc.

The sample room could also be used as the visiting room,and For sampling for quality inspection.

The testing room is used for product production process management and supervision, and it is also convenient for visits and meeting arrangements.Scheduling beer brewing arrangements and production plans.

If you want to ask anything just fill in the form below and send us.