Two vessels craft beer brewing machine,electric heating coil,Energy saving and environmental protection, small size,PLC+HMI automation system,easy to operate,suitable for use on the family balcony.

The features of 10 Gallon home microbrewery kit

When talking about home microbrewery kits,the first product you may think about equipment like the picture shows.There is no doubt that this can indeed brew beer and is the most convenient beer brewing tool,but for people who are truly interested in and passionate about beer brewing,it can restore the brewing process of the brewery and experience the most complete beer. Brewing fun may be a good choice.

How to use the 10 Gallon home microbrewery kit

Different from general home brewing equipment,our 10gallon home microbrewery kit is made of high-quality stainless steel.The combination of two tanks restores the four complete processes of beer brewing into mash/lauter/kettle/whirlpool.The whole set of equipment is welded on skid.

Different from the single layer tanks and plastic bottle,our tanks are jacketed with insulation layer,While improving the heating efficiency,reduce heat loss,ensure the safety of operation and avoid scalding.10 Gallon home microbrewery kit.

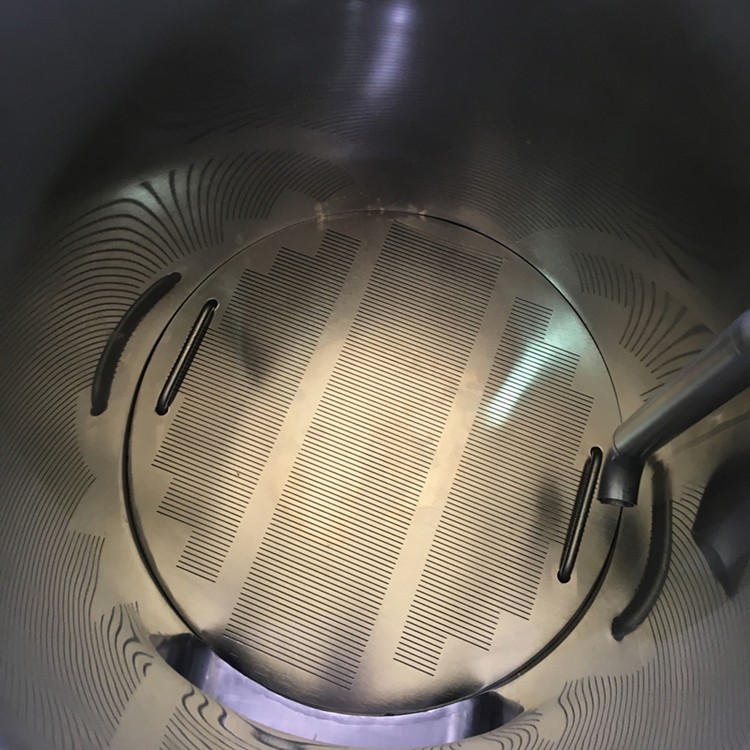

The system are made of two main parts,one is the brewing mash part,two vessels combination,mash tun and lauter share one tank,the mash/lauter tun with a side handhole,plays the function of spent grain remove.top lid is movable,equipped with a cip ball.After the home brewing beer is brewed, it is passed into the pump flushing pipe, and the waste water is discharged from the bottom discharge port.

When the spent grains are washed, the backflow is realized through the pipeline. After the spent grains are washed, the spent grains are discharged manually, and the inner sieve can be removed for easy cleaning.

Cooling system of the 10 Gallon home microbrewery kit

The refrigeration system includes an integrated refrigerator and cold water tank, which are welded to the skid with the fermentation tank, with rollers at the bottom for easy movement. It can be used as beer storage tank and wine selling tank. Jacketed fermentation tank, heat preservation and refrigeration. This part is equipped with PLC and HMI control system. According to different types of beer brewing production requirements, the boiling time and boiling temperature can be set freely, and the electric signal is transmitted through the temperature sensor to realize the automatic control of the system.

Fermentation system of the 10 Gallon home microbrewery kit

The plate heat exchanger is cooled in two stages,and the boiled hot wort is initially cooled by the plate heat exchanger.Then the wort pump is pumped into the fermentation tank,and the cold water provided by the cold water tank circulates in the fermentation tank to achieve constant refrigeration.The temperature error does not exceed 0.5°C.

The number of fermentation tanks can be designed to increase or decrease according to the customer's use place and output requirements.The size can be modified according to the layout of the site and the size of the room.The tank body of the whole set of equipment is easy to connect.We will install and debug the equipment before leaving the factory.After receiving the equipment, customers only need to almost use it.

Accessories of the 10 Gallon home microbrewery kit

Mashing pipeline,cold water pipeline,Equipped with a glass sight glass,which can be used to observe the filter clarity of the wort after the wort is revolved.The top is equipped with searchlight sight glass, thermometer, pressure gauge, liquid level port.The professional equipment configuration can meet the brewing research and use of the brewery laboratory.

Price of the 10 Gallon home microbrewery kit

As for the cost of the whole system,if you want to know more about it,please feel free to contact us.

Configuration list of 10 Gallon home microbrewery kit

Name | Component | Specification | Technical Description | Material |

Mashing system | Mash & lauter tank | 50L | 1.Inner shell is made of SUS304,thickness is 2.5mm,Cladding thickness is 1.5mm 2.Electric heating, 1-1.5℃/min,elliptical manhole, butterfly head 3.Heat-resisting polyurethane foam is used for keeping warm,thickness is 80mm 4.Full capacity of lauter part is 60L 5.Heat-resisting polyurethane foam is used for keeping warm for lauter part,thickness is 80mm 6.Feed on the top of the filter, inlet and flush filter on the same level.The upper 2 root into the tube, one for reflow and wash the worse.Internal bad washing device adopts double umbrella flow plate form, a second washing pipe, used to wash lauter tank, washing ball confirm with ISO standard. 7.Upper lauter with oval endoscopic manhole side out of the discharging mouth;Butterfly tank bottom, lauter out main belt audition and health sampling valve, sight glasses level installation;And the suction lauter,natural lauter can realize , natural filtering can synchronize when washing. 8.Filter plate: milling.Material:SUS304, opening rate is about 10%;Surface light, smooth;Local can open, convenient cleaning, the use of deformation;Filter plate and the distance between the bottom of the pot between 2 to 5 cm, at the bottom of the tank with the cleaning device, uniform not less than three. 9.The thermometer meter is digital display.The precision of platinum thermal resistor is ±0.3℃ .The temperature range is from 1℃ to 120℃ 10.Equipped with cleaning tube, wash ball confirm with ISO standard. | SUS304 |

boiling and whirlpool tank | 50L | 1.Full capacity of is 95l,empty capacity is higher than 40% 2.The inner shell is made of SUS304, thickness is 2.5mm,The cladding thickness is 1.5mm. 3.Polyurethane foam is used to keep warm for the filter tank.The thickness of keeping warm material is 75mm 4.Steam outlet pipeline on the top which diameter is ¢76 for the steam discharging.the steam outlet pipeline will equip with condensed water collecting device and the outlet pipeline should be embedded in the thermal insulation layer 5.Counterclockwise tangential feeding when depositing, feeding port under the liquid level 1/3;With liquid level tube, with a breathing hole, side installation fast loading manhole.The bottom shape and material discharging to insure the effect of depositing as well as to improve the operation convenience, reduce the loss of material liquid.Hanging heavy discharging pipe and drainage pipe between a bypass.With cleaning tube, embedded in the thermal insulation layer. 6.Inner Surface welds polishing process.The apperance is beautiful.Pipeline layout,opening meet the requirement of operation, installation and visiting. 7.Whirlpool tank equipped with cleaning tube, wash ball confirm with ISO standard. | SUS304 | |

Mash support | stainless steel 304 . | SUS304 | ||

Wort pump | 1.5T/H | Sanitary centrifugal pump, pump body and impeller material stainless steel 304, conform to the requirements of the health level of pump;370 w, lift 10 ~ 15 m;Granularity for 3 to 5 mm. | SUS304 | |

Fermentation system | Fermentation tank | Effective volume50L | 1.The inner shell of tank material is SUS304, national standard thickness is 2.5 mm; cladding material is SUS304,thickness is 1.5 mm. 2.Dribbling is used to cool,material is SUS304, thickness is 1.5 mm, withstand voltage is 3 bar , cylindrical cooling temperature area is about 40% of the cylinder surface area , the cones cooling area is about 50% of the surface of the cones. 3.Polyurethane foam is used to keep warm,the thickness is 80 mm. 4.Withstand voltage of tank is 2.5bar 5.60 °hypocone is compressive strength design. 6.Empty capacity is 20%. 7.nternal roughness is less than 0.4 um , no distortion, no scratches, weld highly polishing 8.The upper installation lamp lens. 9.The tank equips with temperature sensor,sample valve,machanical valve.Discharge outlet is at the bottom, beer outlet valve is at the pyramis. 10.Discharge pipe is at the bottom ,the diameter is Ø25。 | SUS304 |

Mechanical valve | Material is SUS304, Rifeng brand | SUS304 | ||

Cooling system | Refrigerator | 1P | 1.Type: air-cooled refrigeration unit. | SUS304 |

Alcohol water tank | 50L | 1.It is made of SUS304, 2.Inner equip with copper evaporator,heat radiating area matches evaporator 3.Automatic temperature control. | SUS304 | |

Alcohol water pump | 0.8T/H | Alcohol water circulating pump, ability to meet the requirements. | ||

Electric System | PLC and touch screen control | 1. Realize special fermentation that is two warming segments, three sections of cooling ; 2. According to different beer can set different fermentation curve, to meet different fermentation technology. 3. Achieve 2-24 hours any cooling speed setting, 4. No duty for fermentation inspection 5. Temperature, time and cycle can be arbitrarily set and modified 6. System capacity meet a fermentation period.System once every 20 minutes collect data and summary,record all data of a fermentation cycle. 7. Traceability. 8. The accuracy of error is plus or minus 0.3 ℃. | SUS304 | |

switchboard | Fermentation &refrigeration shared one, mashing use the other | SUS304 | ||

Fermentation control solenoid valve | 3/4” | Stainless steel spring, fluorine rubber diaphragm, DC24V. | SUS304 | |

Wire and Cable | Signal lines use the shielded wire | SUS304 | ||

threading pipe | 1.Stainless steel decoration pipe,the size & number meet site installation requirements. | SUS304 | ||

Pipeline fittings | Mash line | Φ32 | Including the sugar barrels, saccharifying all valves and piping.Valve shows that manufacturers, including water pipe. | SUS304 |

The alcohol water line | Φ32 | Option 1: one solenoid valve, two ball valve, pipe filters, pipe insulation thickness is 3 cm, outsourcing stainless steel decoration pipe. | SUS304 | |

Φ20 | Option 2: use one solenoid valve, use PPR pipe, 3 cm rubber sponge to keep wartm, outsourcing aluminum foil paper. | PPR | ||

saccharimeter | 0-10,10-20 |

If you want to ask anything just fill in the form below and send us.