Beer is the oldest alcoholic beverage of mankind, based on the transliteration of the English "beer". It was introduced to China as early as a century ago, and developed rapidly after being introduced to China. Beer uses barley malt, hops, and water as the main raw materials, and is a beverage full of carbon dioxide and low alcohol through yeast fermentation.

Speaking of the history of beer, I have to talk about the "pure brewing method." On this day in 1516, Grand Duke Wei and IV of Baderia promulgated a law stating that only barley, water and hops should be used for beer brewing. At this time, everyone did not know the existence of yeast, so to say that this great law now seems to be a joke. The reason for rushing to enact this law at that time was because for different purposes, brewers randomly added things, such as medicinal materials and spices, to the wine, which almost messed up the entire beer market. But this flawed law and the Germans who were directly held up by the Germans have continued to this day. Become the oldest provisions on food safety.

But for modern brewers, beer brewing is no longer limited to barley, water and hops. The ultimate consumption experience is the most important.

Home brewing is characterized by small output, more flexible production, and low investment cost. It only requires a small set of mash equipment to complete beer production. It is the best choice for home beer brewing enthusiasts. In addition, home-brewed beer can also be individualized according to the taste of the beer brewer. Lime, citrus, mango, passion fruit, honey, and even green pepper are all tried and successful.

WEMAC home brewing beer equipment is to take into account the needs of home brewing, and the experience of brewing is completely handed over to customers. From 30L mini brewing mash machine to 100L mini craft beer mash system, they are all our scope of supply, and the equipment is firm. Stable and durable. The electric heating tube is adopted, and the energy consumption is low.

The refrigerator is combined with a cold water tank and a heat exchanger to quickly cool the wort after mashing to the fermentation temperature.

The whole set of equipment is welded into the same tube frame, compact structure, and the bottom with rollers, can be easily moved.

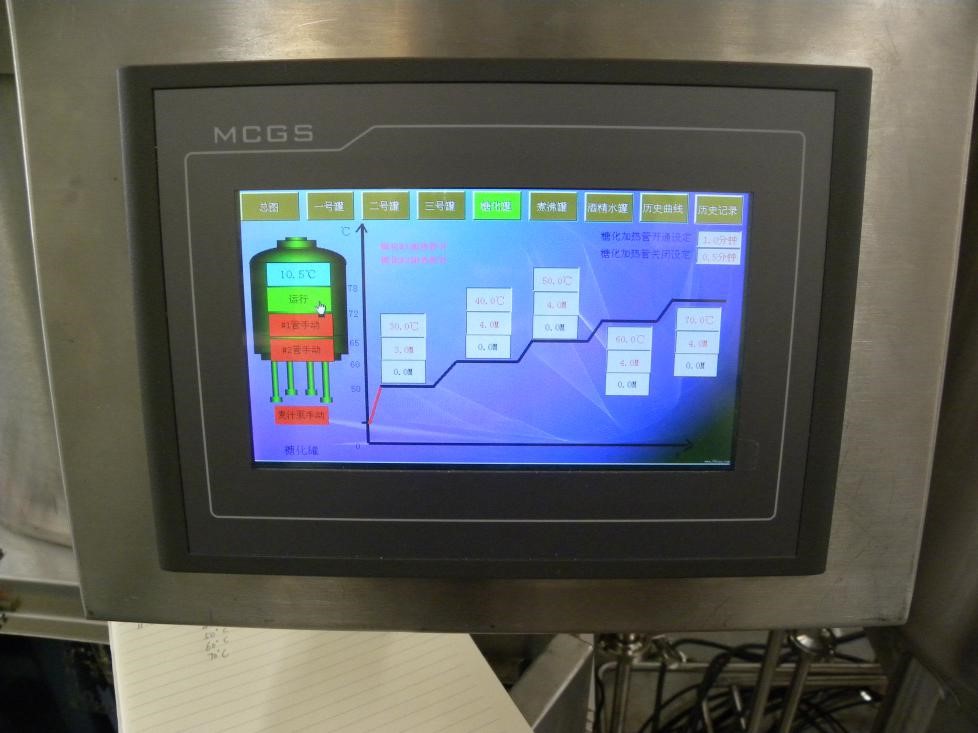

The fermentation tank and mash tun are equipped with temperature sensors, and with the PLC control system, the temperature and time can be automatically controlled according to the set program.

As shown in the picture is the site of the 500L saccharification equipment designed and constructed by WEMAC.

Beer fermentation system-500L fermentation tank is placed inside the bar, so that consumers can pay attention to the equipment when drinking. People understand beer far more than beer brewing equipment, so this has become a major feature of the store. Six 500L beer fermentation tanks can produce at least 6000L of beer per month according to a 15-day beer fermentation cycle, which can meet the drinking needs of hundreds of people every day. In addition, the fermentation tank is connected to the refrigeration system, so there is no need for a separate freezer to cool the beer, reducing operating costs. The fermentation tank is equipped with a refrigeration jacket, Miller board refrigeration, polyurethane filling insulation, a 60/75° cone design at the bottom, and a rotating cleaning spray ball inside.The top of each fermentation tank is equipped with a hop injection port, which is matched with a hop addition tank, which is convenient to operate and will not cause pollution.

60L fermenter for Home brewer&beer lover

WEMAC is a large beer equipment manufacturer, including large, medium and small beer saccharification equipment and brewing equipment are our scope of supply. If you have the idea of establishing or expanding beer brewing plants and distributing beer systems, we will make you Second choice, the following is an introduction to the 60L small beer fermentation tank, I hope it will help you to choose a fermentation tank.

This picture is a fermentation tank design drawing designed by WEMAC engineers for customers. It is different from the large inventory of traditional beer equipment manufacturers. WEMAC takes more into account the consumer’s intentions and ideas during the product design and production stage. Different customers The needs of equipment are different, and what our experienced engineers do is to allow customers to participate in the design of the equipment as much as possible after taking into account the convenience and feasibility of equipment production and use to ensure that the finished product is fermented.

WEMAC has a large-scale production workshop and advanced factory building experience. When the quality is guaranteed, the products are delivered for use. Customers can inspect the goods on site before delivery, and ship the products after they are satisfied.

The following pictures can show the detailed information of the fermentation tank more clearly:

The whole is made of high-quality stainless steel. The inner material is 2MM thick, the outer material is 3MM, and the jacket is 80MM between the inner and outer materials. The jacket is filled with polyurethane foam, and the heat preservation effect is excellent. The top manhole, two thirds of the top is a pressure regulating valve, there is a carbon dioxide aeration hole in the middle, the lowest part of the cone bottom is the sewage outlet, the beer residue in the fermentation tank is discharged from here, the top of the sewage outlet is the beer outlet for fermentation The finished beer is discharged from there. A cold water pipe is embedded in the jacket, and the cold water is cooled by the Miller plate.

It is welded with argon gas, no welding scar, and the welding part is polished.

For the valves, pipes, pressure and other accessories on the fermentation tank, we will give customers free accessories to avoid damage during transportation or use and ensure customers' worry-free use.

Parameter Description:

1. The inner tank is made of SUS304, thickness 3mm; the outer material is SUS304, thickness 2mm; external dimensions: D=508mm, H=400mm.

2. Miller board jacket, material SUS304, thickness 1.5mm, the cooling area of the cylinder body is about 40% of the surface area of the cylinder, and the cooling area of the head is about 50% of the surface area of the head.

3. Polyurethane foam insulation, thickness 65mm.

4. The pressure of the tank is 3bar.

5. 20% empty capacity. The upper part of the cylinder of the tank is flush with the bottom of the washing ball,

6. Equipped with a washing ball, the installation position is slightly lower than the welding seam between the cylinder and the head, and the cleaning pipe Ø32

7. The internal roughness is less than or equal to 0.4um, and there is no deformation or scratches, and the welding seam is 2B surface.

8. Tank top device is installed on the upper part.

9. The tank body is equipped with integrated searchlight sight glass; there is a wine outlet at the bottom.

10. The bottom drain pipe Ø32.

11. The internal 2B surface of the equipment, pickling passivation treatment, external surface drawing treatment, beautiful appearance, pipeline layout, opening position, etc. meet the requirements of operation, site installation.

As a professional beer equipment manufacturer, WEMAC are looking for partners worldwide. If you are interested in equipment or have equipment distribution experience, please contact us in time, we can help you expand your local influence and occupy the local small home brew The market for beer equipment.

It's not hard to make beer at home. Find a place at home, draw a good drawing and give it to the brewery equipment manufacturer. Professional brewery, will give you professional advice and beer equipment assembly program.

WEMAC has rich factory building experience. If you are interested in beer brewing and want to own your own bar, please do not hesitate to contact us and look forward to your visit.

Commercial beer equipment is at the heart of the modern brewing industry. This article will look at 2000 liter commercial beer equipment, a moderately sized brewing system suitable for small to medium sized bars, restaurants and breweries. We'll learn about its key components, operational processes, and the business considerations associated with them.

More >>

Brewing system: The Restaurant Nano Brewery Equipment brewing system is the heart of any brewery, and a nano brewery is no exception. Restaurant Nano Brewery Equipment typically consists of a mash tun, brew kettle, and fermenter. The size of the brewing system will depend on the amount of beer you plan to brew, but for a restaurant nano brewery, a 1- or 2-barrel system is common.

More >>

Craft brewery equipment is widely used in medium breweries and beer pubs. It can brew pale lager, amber lager, dark lager, ale and etc at proper temperature with different raw material.

More >>

A complete set of 500L beer equipment consists of malt crushing system, saccharification system, fermentation system, steam system, refrigeration system, CIP cleaning system, pipeline system, etc. 500L brewing beer equipment is generally used in commercial, restaurants, bars, barbecue shops and other places.

More >>

100L beer equipment can be used in home brewing and business. Each batch can produce 100L beer, and two batches can be made every day, up to 200L beer. If you are at home, you can produce beer every few days. If it is commercial, first of all, it is necessary to determine how many liters of beer are produced a day. The 100L beer equipment can produce up to three batches a day, but considering the labor intensity, it can produce up to one or two batches a day. The number of fermentation tanks is determined according to the amount of beer produced.

More >>

Small beer equipment is generally divided into two types, one is small household simple equipment, and the other is commercial beer equipment. Small household simple equipment generally refers to 30l-100l, with small floor area, convenient operation and relatively simple technology. Commercial beer equipment generally refers to 300l-2000l beer equipment. Now the popular fine brewing beer equipment in the market is made with this equipment.

More >>

The 100L micro beer equipment belongs to a small beer brewing system. Small space, high degree of automation, simple and easy to operate. The mash process is electric heating, which is generally equipped with two device specifications (mashing+lautering + boiling+whirlpool), with ice water tank, plate heat exchanger, wort oxygenator, wort pump, etc; The fermentation process is automatically controlled by PLC, and 6 fermentation tanks are generally configured according to the standard. It belongs to self entertainment beer brewing equipment.

More >>

If you are planning to build a brewery, you must consider the turnkey beer project. What is the whole turnkey beer production line like? Which manufacturers can do a good job in this beer production line? What problems should we pay attention to? The beginning of a new project certainly requires a lot of preparatory work and a lot of problems. Many times, it is very difficult. This professional problem should be solved by a professional company. We can provide you with the turnkey work of the whole beer project, with more than 60 years of production experience.

More >>

As a popular drink, more and more people like to brew beer. How is beer brewed? According to beer concentration, it is divided into high concentration beer, medium concentration beer and low concentration beer. According to the production mode, it is divided into: fresh beer, pure draft beer and cooked beer. No matter what kind of beer, the beer brewing system is divided into: malt crushing system, saccharification system, fermentation system, CIP cleaning system, refrigeration system, control system, filling system and water treatment system.

More >>

As one of the oldest beverages in the world, beer has a history of 4000-5000 years. It uses malt as the main raw material, adds hops, and is brewed by yeast. Craft beer is actually an innovation movement in the beer industry. Behind it is the rise of the young consumers born in the 80s and 90s. They have higher requirements for consumer experience, personalization and diversification.

More >>

For beer equipment, each customer has different requirements. We have talked about what equipment beer equipment needs, how to choose beer equipment, and what is the most suitable scheme? According to the different needs of each customer, today we will talk about the additional configuration of beer equipment, so that we can use it better and more conveniently to brew higher quality beer.

More >>

As the core of the whole beer equipment, saccharification system is the key to brewing beer, so how to choose the saccharification system suitable for you? As we all know, the saccharification system is divided into four steps: saccharification - Filtration - boiling - spin sedimentation. In order to achieve the desired effect in each step and save cost, the combination of saccharification system is very key.

More >>